Subaru Outback (BR): General Description of Continuously Variable Transmission

A: SPECIFICATION

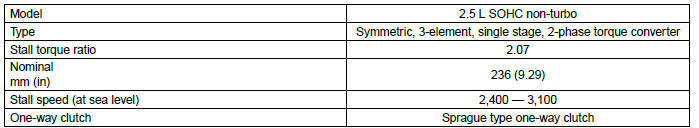

1. TORQUE CONVERTER

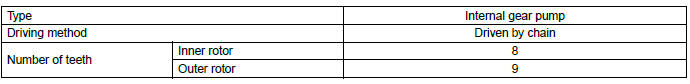

2. OIL PUMP

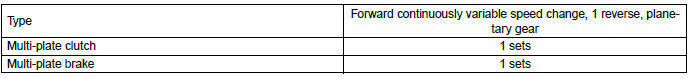

3. TRANSMISSION CONTROL ELEMENT

4. TRANSMISSION GEAR RATIO

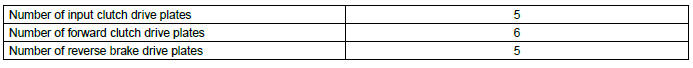

5. PLATE

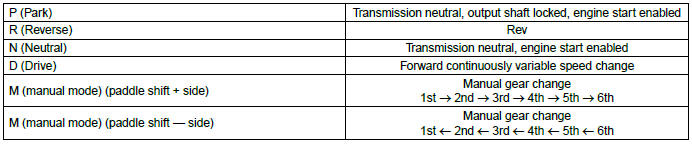

6. SELECTOR POSITION

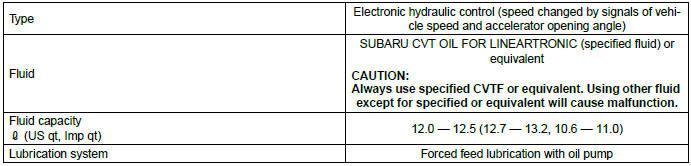

7. HYDRAULIC CONTROL AND LUBRICATION

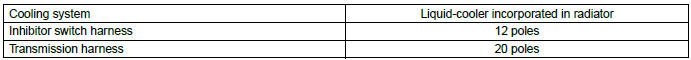

8. COOLING AND HARNESS

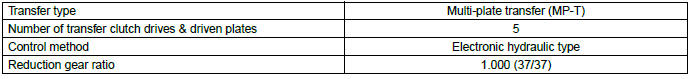

9. TRANSFER

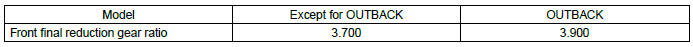

10.REDUCTION GEAR RATIO

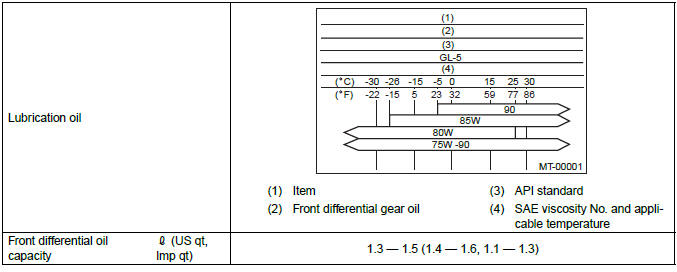

11.RECOMMENDED GEAR OIL

B: COMPONENT

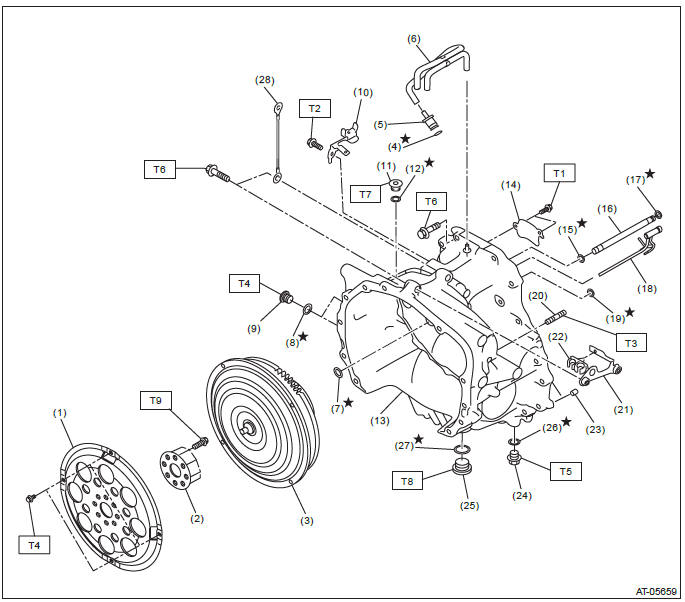

1. TORQUE CONVERTER ASSEMBLY AND CONVERTER CASE

- Drive plate

- Reinforcement drive plate

- Torque converter ASSY

- O-ring

- Oil charge pipe cap

- Air breather hose ASSY

- O-ring

- O-ring

- Plug

- Transmission harness stay

- Plug

- O-ring

- Converter case

- Oil stopper plate

- O-ring

- Lubrication pipe

- O-ring

- Lubrication pipe

- O-ring

- Stud bolt

- Transmission hanger

- Clip

- Straight pin

- Overflow drain plug

- Front differential gear oil drain plug

- Gasket

- Gasket

- Transmission radio ground cord

Tightening torque: N*m (kgf-m, ft-lb)

T1: 9 (0.9, 6.6)

T3: 18 (1.8, 13.3)

T4: 25 (2.5, 18.4)

T5: 35 (3.6, 25.8)

T6: 41 (4.2, 30.2)

T7: 50 (5.1, 36.9)

T8: 70 (7.1, 51.6)

T9: <Ref. to CVT-133, INSTALLATION, Drive Plate.>

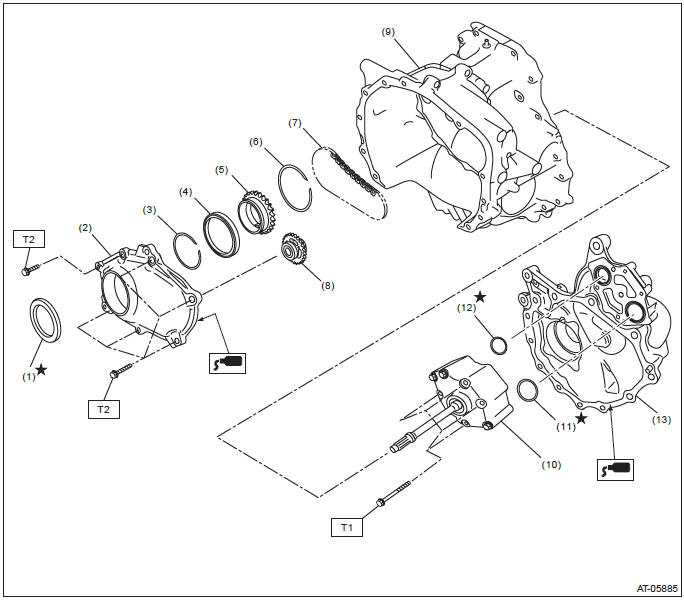

2. OIL PUMP ASSY

- Oil seal

- Oil pump chain cover

- Snap ring

- Ball bearing

- Drive sprocket

- Snap ring

- Oil pump chain

- Driven sprocket

- Converter case

- Oil pump ASSY

- O-ring (large)

- O-ring (small)

- Drive pinion retainer

Tightening torque: N*m (kgf-m, ft-lb)

T1: 8.5 (0.9, 6.3)

T2: 24 (2.4, 17.7)

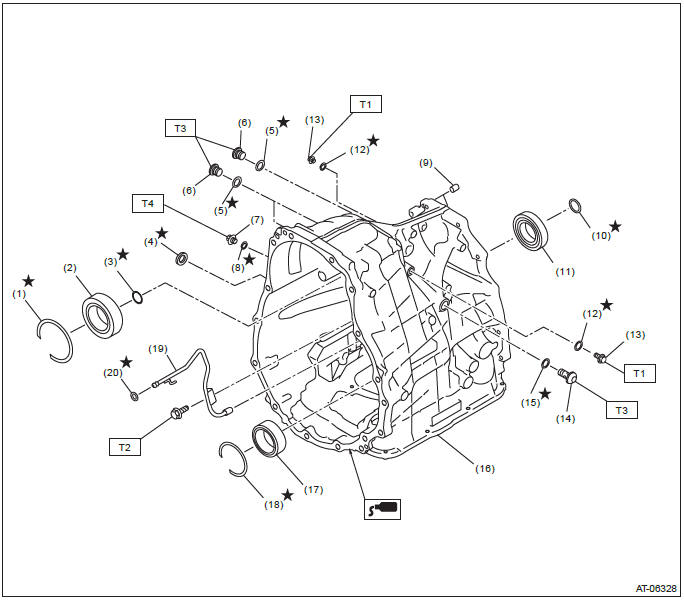

3. TRANSMISSION CASE

- Snap ring

- Roller bearing

- Seal ring

- Oil seal

- O-ring

- Plug

- Plug

- Gasket

- Straight pin

- Seal ring

- Ball bearing

- O-ring

- Plug

- Plug

- O-ring

- Transmission case

- Roller bearing

- Snap ring

- Lubrication pipe

- O-ring

Tightening torque: N*m (kgf-m, ft-lb)

T1: 13 (1.3, 9.6)

T2: 16 (1.6, 11.8)

T3: 25 (2.5, 18.4)

T4: 35 (3.6, 25.8)

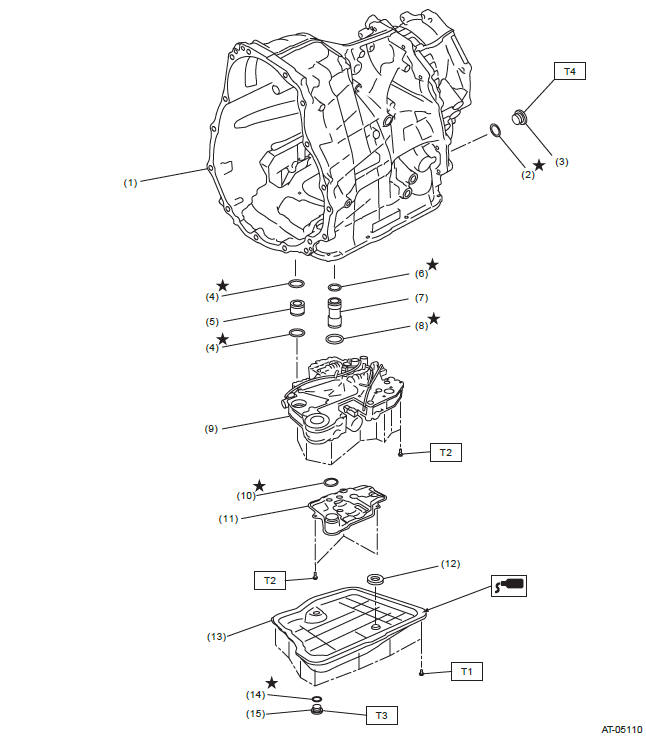

4. CONTROL VALVE BODY

- Transmission case

- Gasket

- Filler plug

- O-ring

- Pressure pipe

- O-ring (small)

- CVTF pipe

- O-ring (large)

- Control valve body

- O-ring

- Oil strainer

- Magnet

- Oil pan

- Gasket

- CVTF drain plug

Tightening torque: N*m (kgf-m, ft-lb)

T1: 5 (0.5, 3.7)

T2: 9 (0.9, 6.6)

T3: 20 (2.0, 14.8)

T4: 50 (5.1, 36.9)

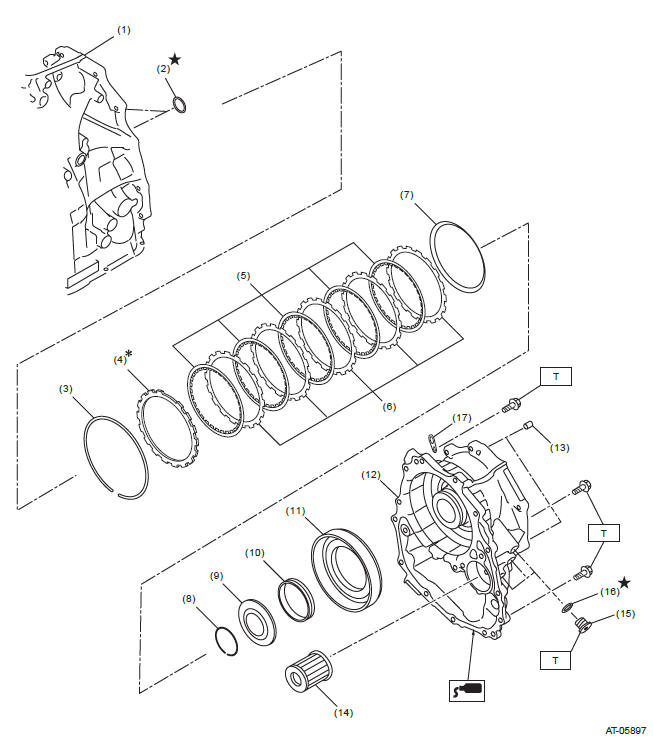

5. REVERSE BRAKE ASSEMBLY AND INTERMEDIATE CASE

- Transmission case

- O-ring

- Snap ring

- Retaining plate

- Drive plate

- Driven plate

- Dish plate

- Snap ring

- Spring retainer

- Return spring

- Reverse brake piston

- Intermediate case

- Straight pin

- CVTF filter

- Plug

- O-ring

- Transmission hanger

Tightening torque: N*m (kgf-m, ft-lb)

T: 25 (2.5, 18.4)

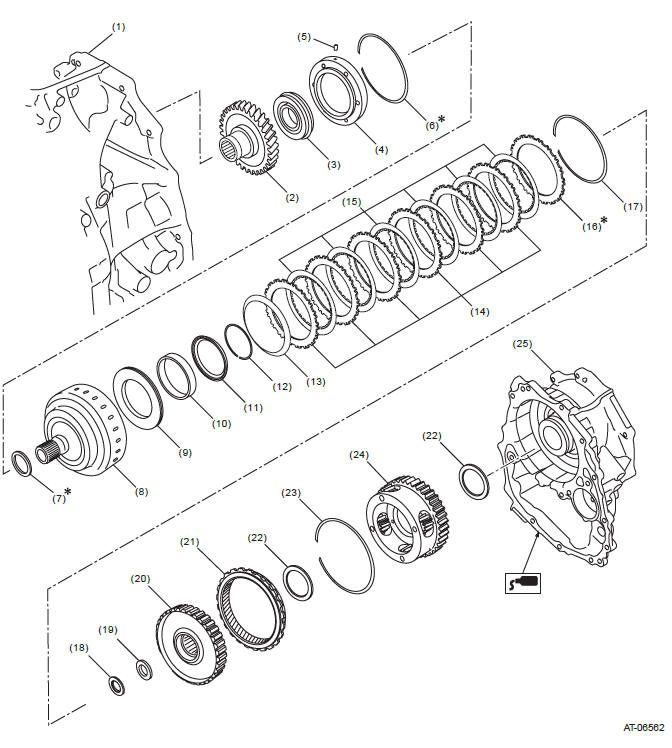

6. FORWARD CLUTCH ASSEMBLY AND REDUCTION DRIVEN GEAR

- Transmission case

- Reduction driven gear

- Ball bearing

- Reduction driven gear retainer

- Straight pin

- Snap ring

- Washer

- Forward clutch drum

- Forward clutch piston

- Return spring

- Forward clutch piston retainer

- Snap ring

- Dish plate

- Driven plate

- Drive plate

- Retaining plate

- Snap ring

- Thrust needle bearing

- Washer

- Sun gear ASSY

- Internal gear

- Thrust needle bearing

- Snap ring

- Planetary carrier ASSY

- Intermediate case

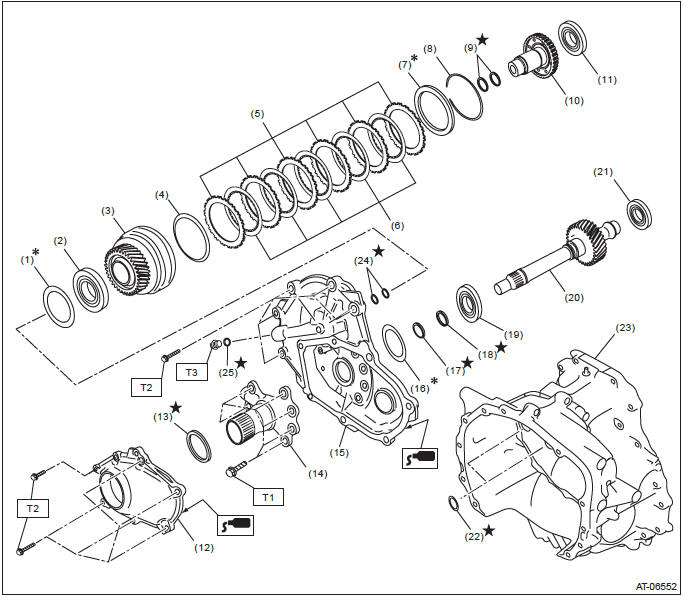

7. FRONT REDUCTION DRIVE GEAR AND FRONT REDUCTION DRIVEN GEAR

- Shim

- Ball bearing

- Front reduction driven gear

- Dish plate

- Driven plate

- Drive plate

- Retaining plate

- Snap ring

- Seal ring

- Front reduction driven shaft

- Ball bearing

- Ball bearing

- Seal ring

- Center support COMPL

- Converter case cover

- Shim

- O-ring

- Seal ring

- Ball bearing

- Front reduction drive gear

- Ball bearing

- O-ring

- Converter case

- Seal ring

- O-ring

Tightening torque: N*m (kgf-m, ft-lb)

T1: 21.5 (2.2, 15.9)

T2: 24 (2.4, 17.7)

T3: 25 (2.5, 18.4)

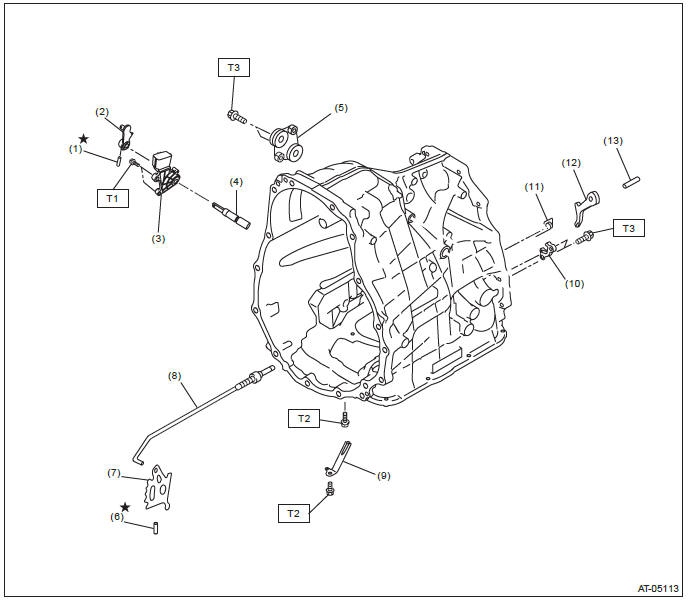

8. TRANSMISSION CONTROL DEVICE

- Spring pin

- Shifter arm

- Inhibitor switch

- Shifter arm shaft

- Plate ASSY

- Spring pin

- Manual plate

- Parking rod

- Detent spring

- Parking support

- Return spring

- Parking pawl

- Shaft

Tightening torque: N*m (kgf-m, ft-lb)

T1: 5 (0.5, 3.7)

T2: 7 (0.7, 5.2)

T3: 25 (2.5, 18.4)

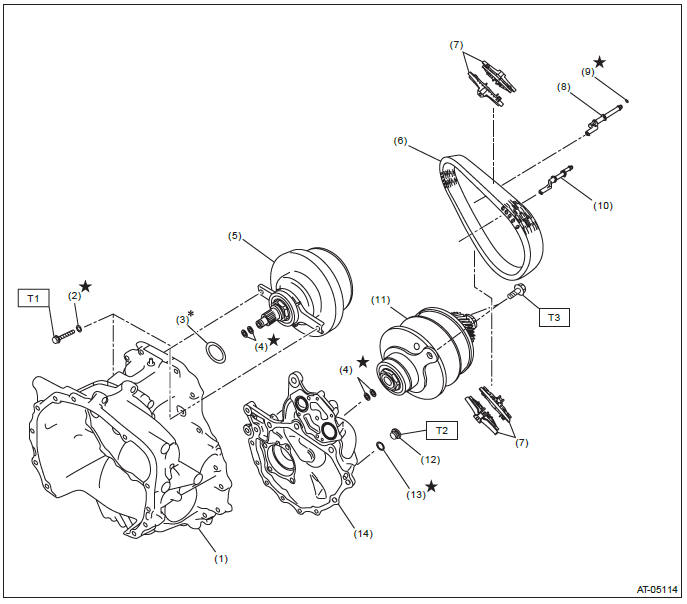

9. PRIMARY PULLEY, SECONDARY PULLEY AND VARIATOR CHAIN

- Converter case

- Seal washer

- Shim

- Seal ring

- Primary pulley ASSY

- Variator chain

- Chain guide

- Lubrication pipe

- O-ring

- Support rod

- Secondary pulley ASSY

- Plug

- O-ring

- Drive pinion retainer

Tightening torque: N*m (kgf-m, ft-lb)

T1: 21 (2.1, 15.5)

T2: 25 (2.5, 18.4)

T3: 33 (3.4, 24.3)

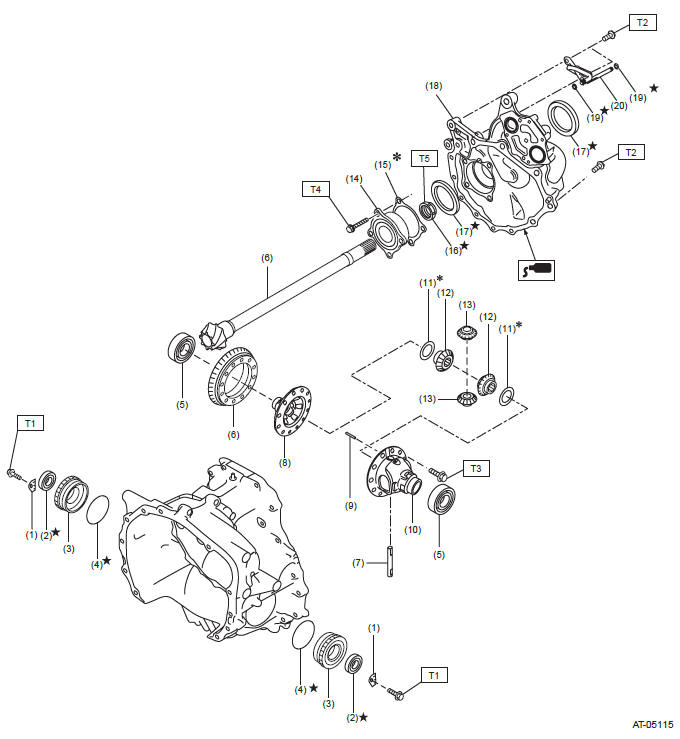

10.FRONT DIFFERENTIAL GEAR

- Lock plate

- Oil seal

- Differential side retainer

- O-ring

- Taper roller bearing

- Drive pinion gear set

- Pinion shaft

- Differential case RH

- Straight pin

- Differential case LH

- Washer

- Differential bevel gear

- Differential bevel pinion

- Taper roller bearing

- Shim

- Lock nut

- Oil seal

- Drive pinion retainer

- O-ring

- Lubrication pipe

Tightening torque: N*m (kgf-m, ft-lb)

T1: 25 (2.5, 18.4)

T2: 43 (4.4, 31.7)

T3: <Ref. to CVT-271, DIFFERENTIAL CASE ASSY, ASSEMBLY, Front Differential Assembly.

T4: 70 (7.1, 51.6)

T5: 130 (13.3, 95.9)

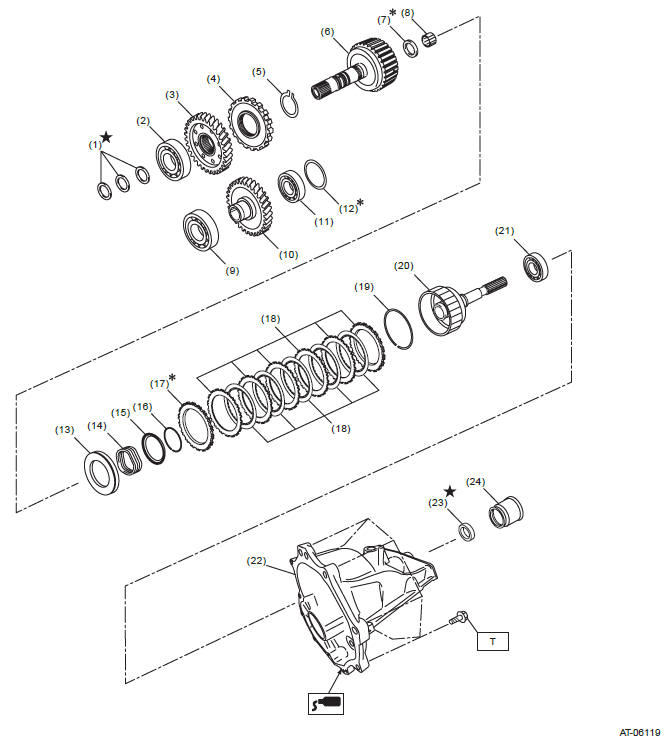

11.TRANSFER AND EXTENSION CASE

- Seal ring

- Ball bearing

- Transfer drive gear

- Parking gear

- Snap ring

- Reduction drive gear shaft

- Thrust needle bearing

- Needle bearing

- Ball bearing

- Transfer reduction driven gear

- Ball bearing

- Shim

- Transfer piston

- Return spring

- Transfer piston seal

- Snap ring

- Pressure plate

- Transfer clutch plate set

- Snap ring

- Rear drive shaft

- Ball bearing

- Extension case

- Oil seal

- Dust cover

Tightening torque: N*m (kgf-m, ft-lb)

T: 25 (2.5, 18.4)

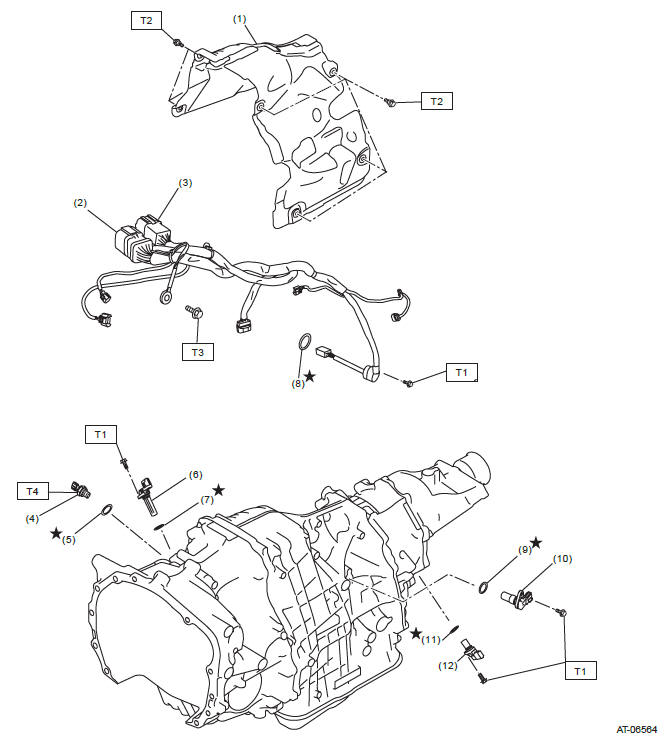

12.TRANSMISSION HARNESS AND SENSOR

- Transmission cover

- Transmission harness

- Inhibitor harness

- Secondary pressure sensor

- O-ring

- Primary speed sensor

- O-ring

- O-ring

- O-ring

- Secondary speed sensor

- O-ring

- Front wheel speed sensor

Tightening torque: N*m (kgf-m, ft-lb)

T1: 5 (0.5, 3.7)

T2: 8 (0.8, 5.9)

T3: 16 (1.6, 11.8)

T4: 39 (4.0, 28.8)

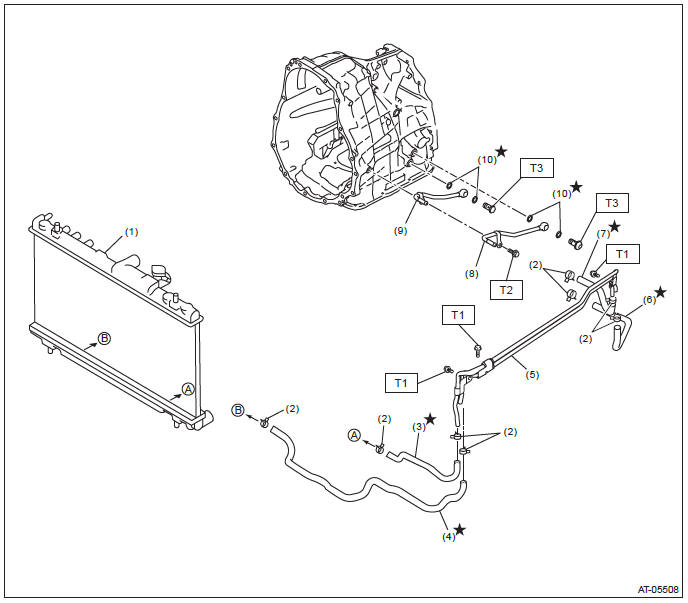

13.CVTF COOLER PIPE AND HOSE

- Radiator

- Clip

- CVTF radiator outlet hose

- CVTF radiator inlet hose

- CVTF cooler pipe ASSY

- CVTF CVT inlet hose

- CVTF CVT outlet hose

- CVTF outlet pipe

- CVTF inlet pipe

- Gasket

Tightening torque: N*m (kgf-m, ft-lb)

T1: 7.5 (0.76, 5.5)

T2: 16 (1.6, 11.8)

T3: 40 (4.1, 29.5)

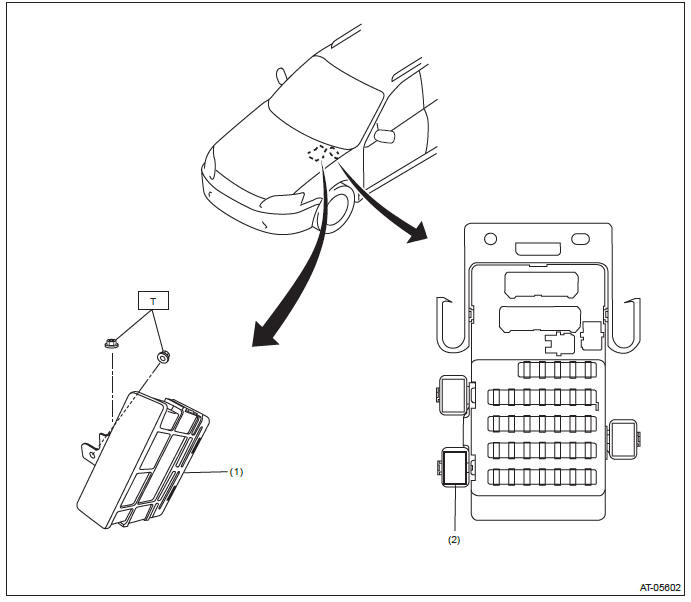

14.TRANSMISSION CONTROL MODULE

- Transmission control module (TCM)

- Relay

Tightening torque: N*m (kgf-m, ft-lb)

T: 7.5 (0.75, 5.5)

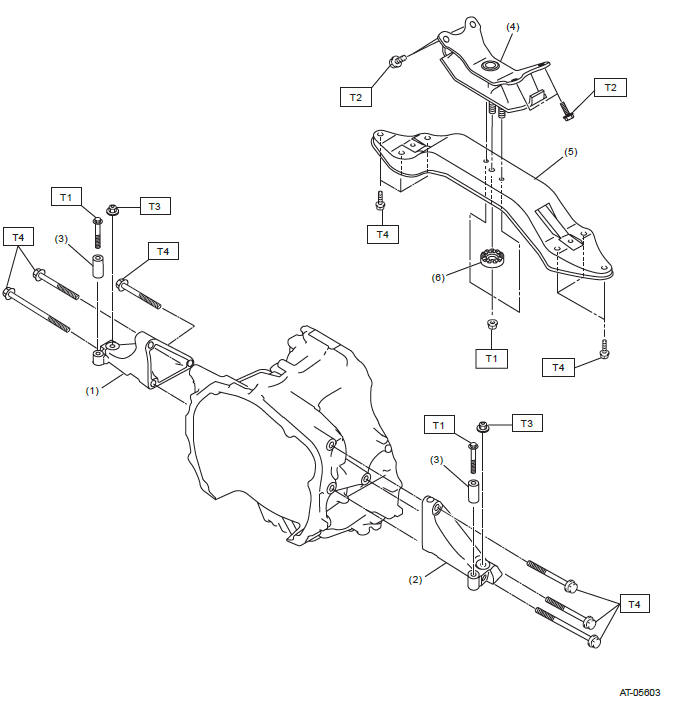

15.TRANSMISSION MOUNTING

- Transmission mounting bracket (RH)

- Transmission mounting bracket (LH)

- Collar

- Rear cushion rubber

- Transmission rear crossmember

- Stopper

Tightening torque: N*m (kgf-m, ft-lb)

T1: 35 (3.6, 25.8)

T2: 40 (4.1, 29.5)

T3: 45 (4.6, 33.2)

T4: 75 (7.6, 55.3)

C: CAUTION

- Wear appropriate work clothing, including a cap, protective goggles and protective shoes when performing any work.

- Remove contamination including dirt and corrosion before removal, installation or disassembly.

- Keep the disassembled parts in order and protect them from dust and dirt.

- Do not place the oil pan with its inner side facing up until it is installed, to prevent intrusion of foreign matter into the control valve body.

- Before removal, installation or disassembly, be sure to clarify the failure. Avoid unnecessary removal, installation, disassembly and replacement.

- When disassembling the case and other light alloy parts, use a plastic hammer to force it apart. Do not pry apart with screwdrivers or other tools.

- Vehicle components are extremely hot after driving. Be wary of receiving burns from heated parts.

- Use SUBARU genuine CVTF and recommended grease. Do not mix CVTF, grease etc. of different grades or manufacturers.

- Be sure to tighten bolts and nuts to the specified torque.

- Place lifts, shop jacks or rigid racks at specified locations.

- Apply CVTF onto sliding or revolving surfaces before installation.

- Replace deformed or damaged snap rings with new parts.

- Before installing O-rings or oil seals, apply sufficient amount of CVTF to avoid damage and deformation.

- Be careful not to incorrectly install or fail to install O-rings, snap rings and other such parts.

- Before securing a part on a vise, place cushioning material such as wood blocks, aluminum plate, or cloth between the part and the vise.

- Avoid damaging the mating surface of the case.

- Before applying liquid gasket, completely remove the old liquid gasket.

- After removing the sensors, breather hose and plugs, plug the holes to avoid foreign materials intruding as necessary.

- During disassembly or assembly, be sure to use nylon gloves or paper towels. Do not use cloth gloves or waste cloth.

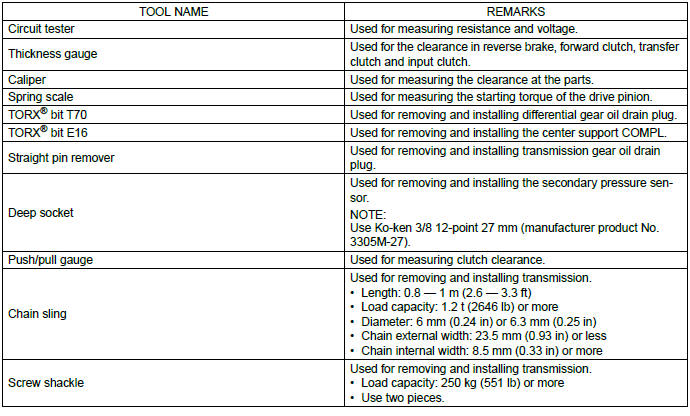

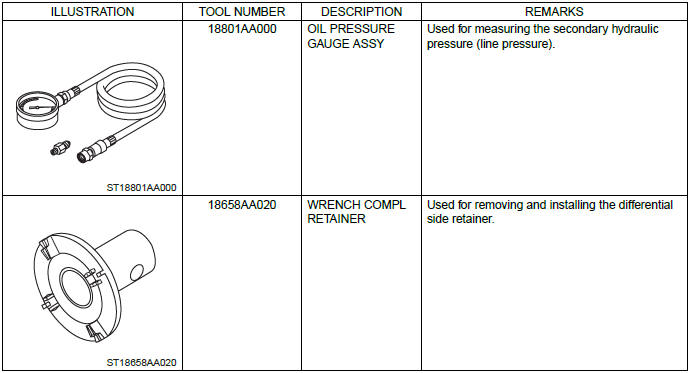

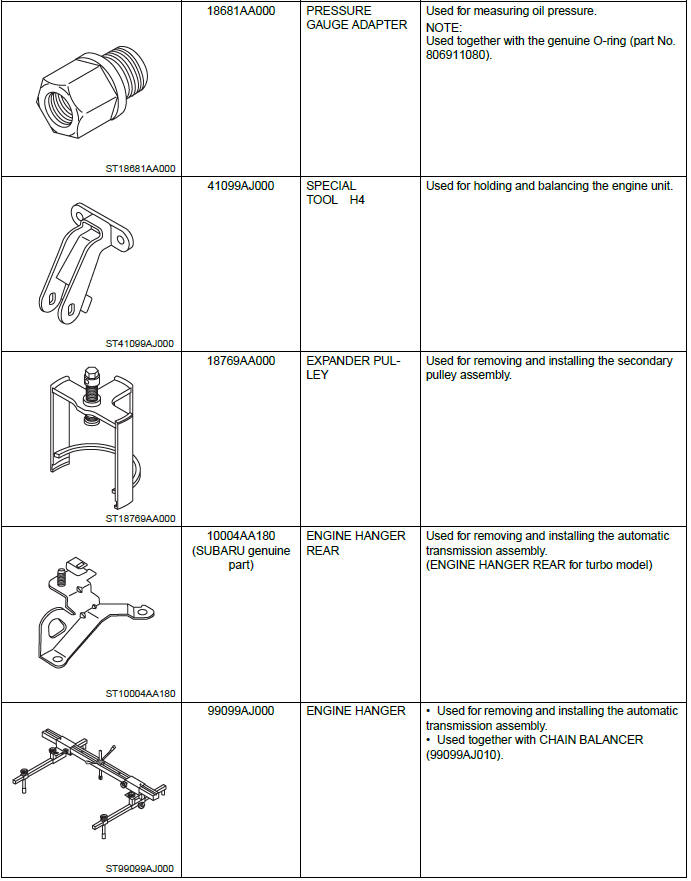

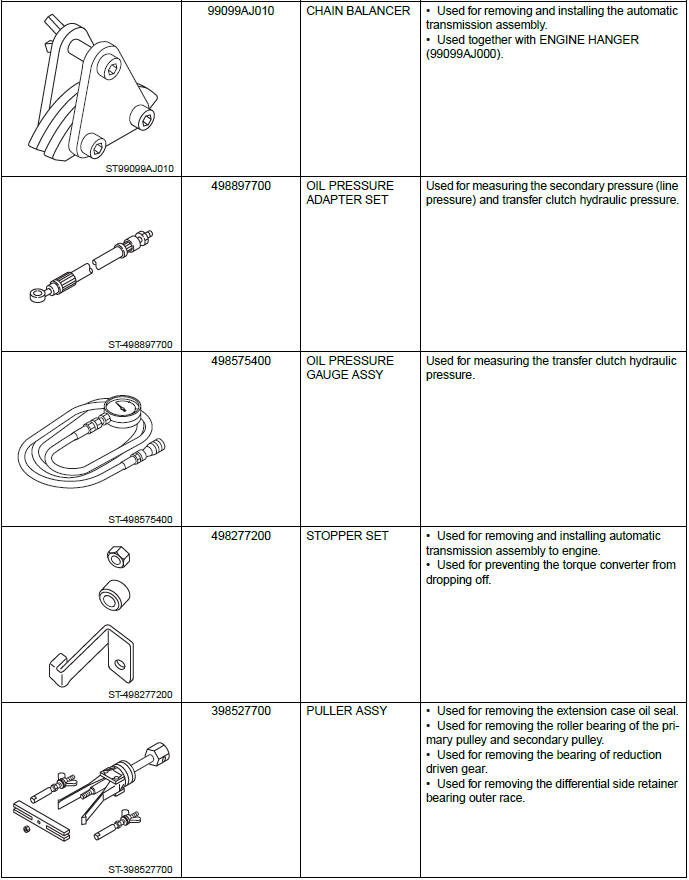

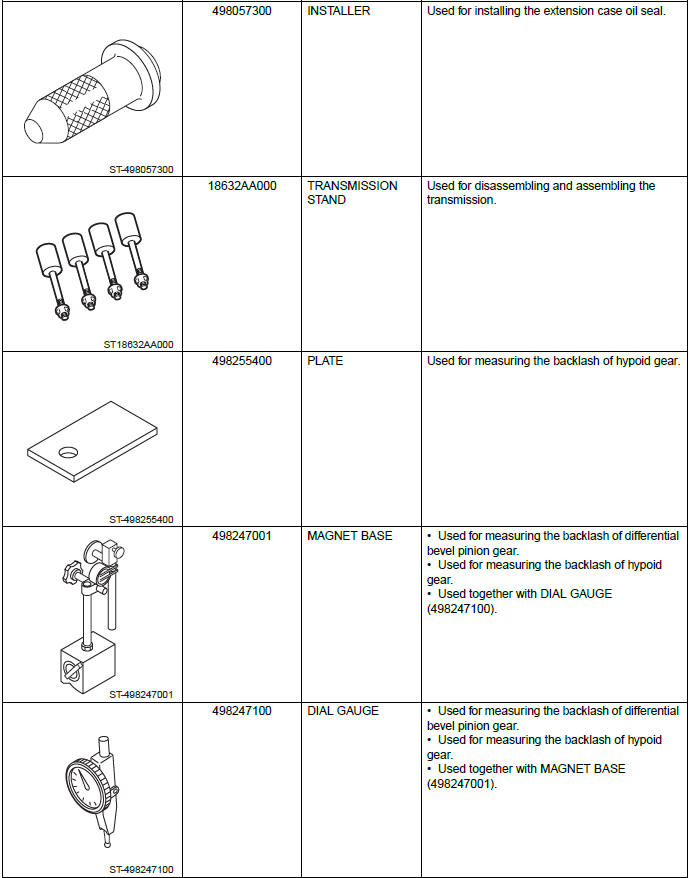

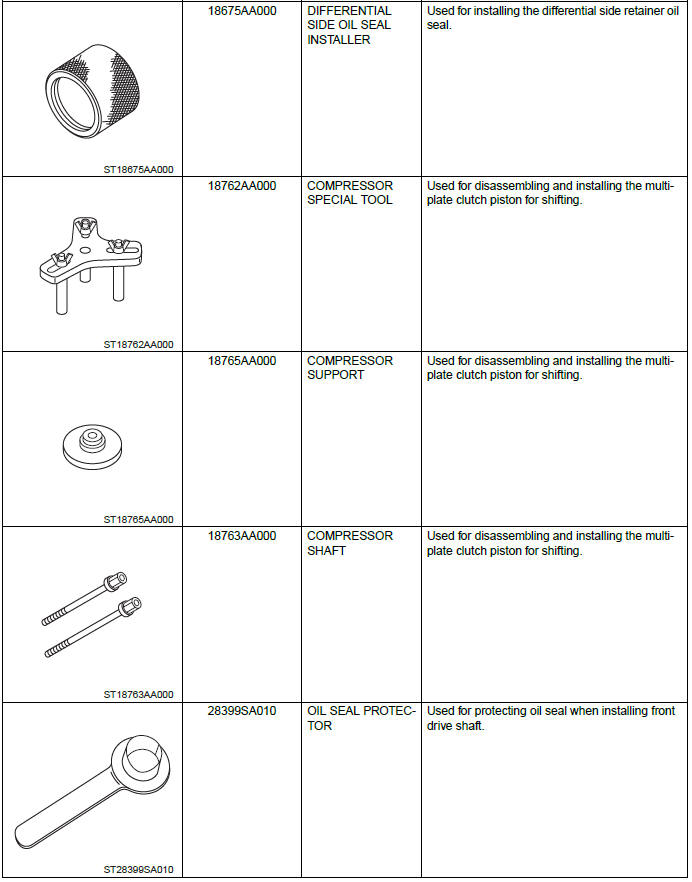

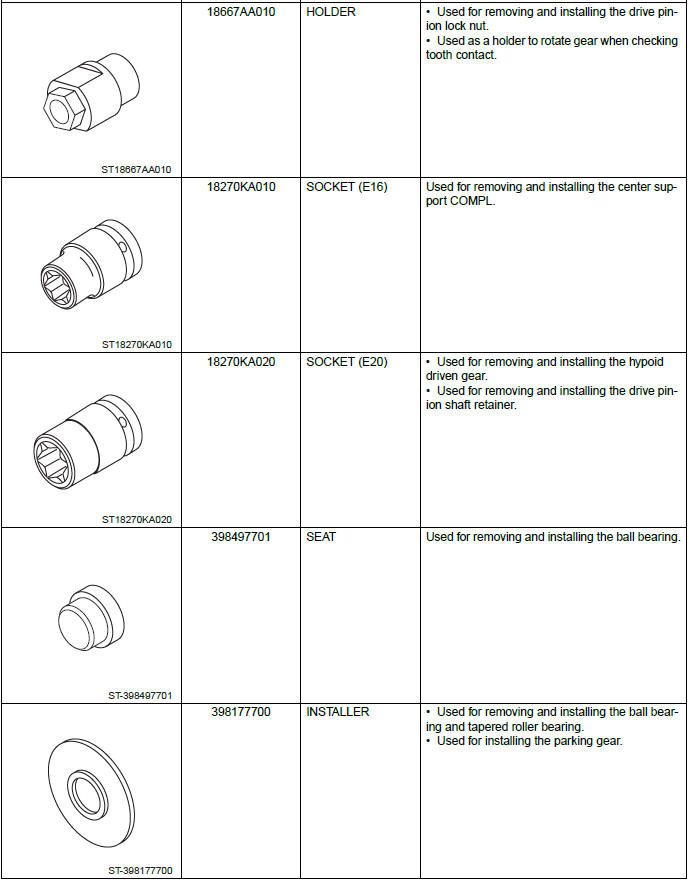

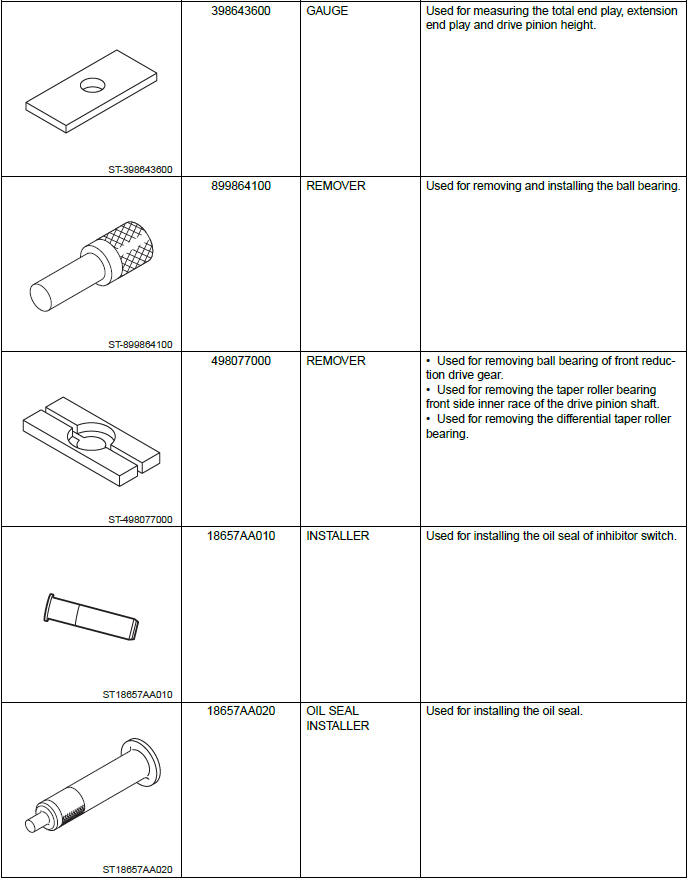

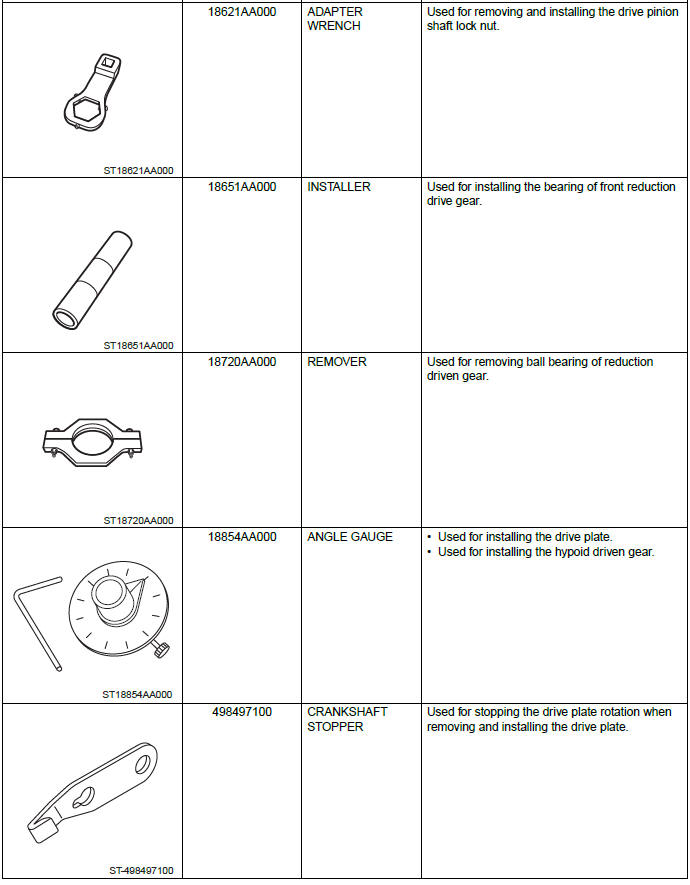

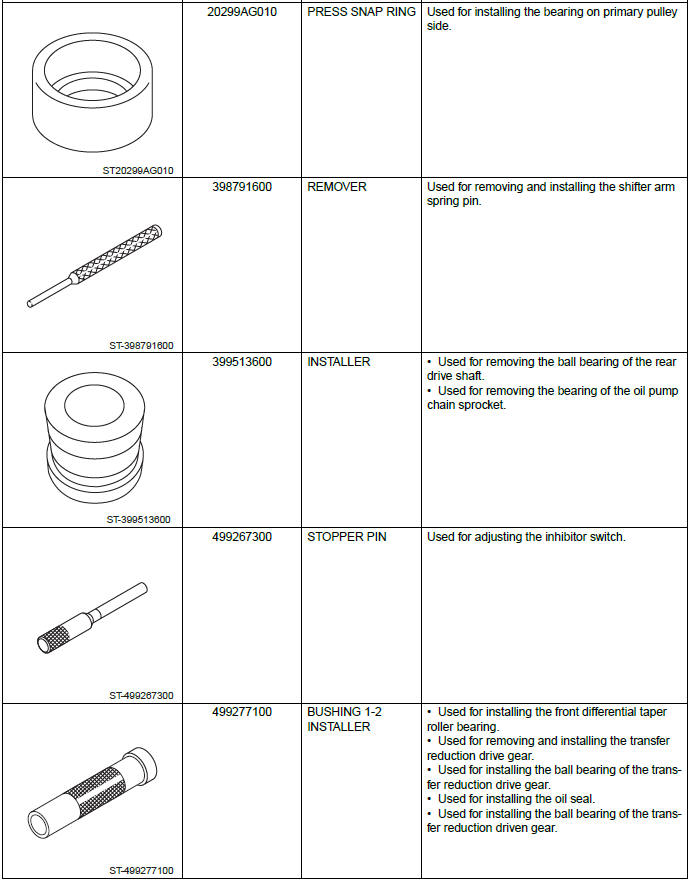

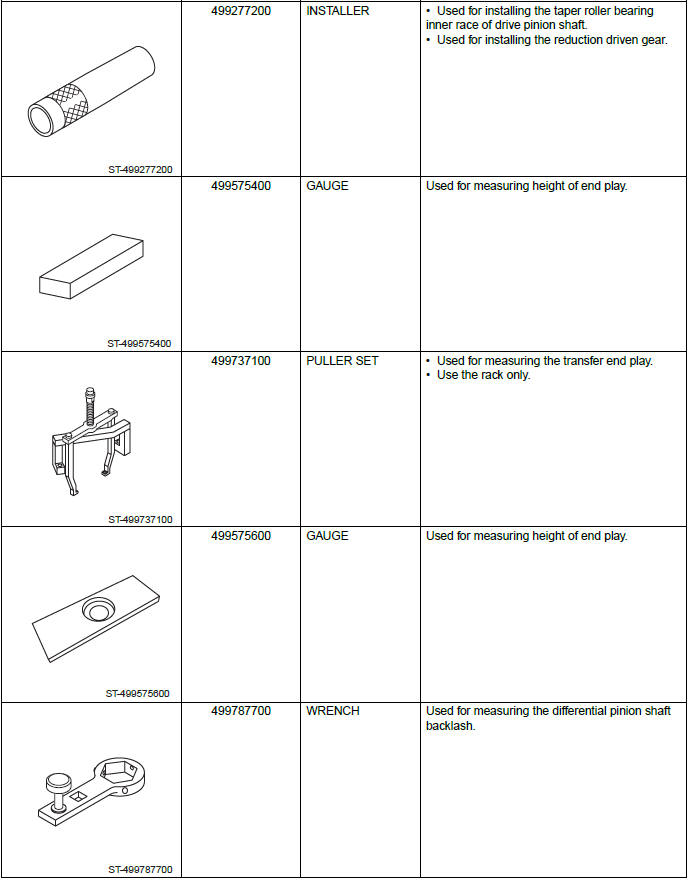

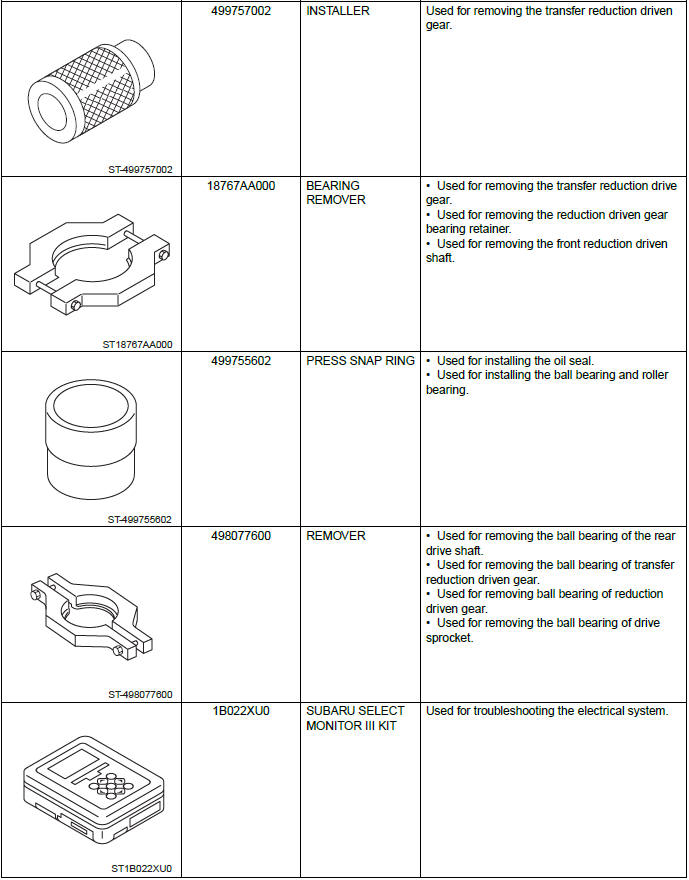

D: PREPARATION TOOL

1. SPECIAL TOOL

2. GENERAL TOOL