Subaru Outback (BR): General Description of Clutch System

Subaru Outback (BR) 2010-2015 Service Manual / Transmission / Clutch System / General Description of Clutch System

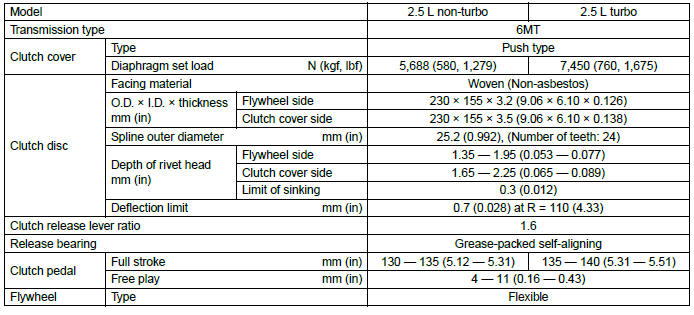

A: SPECIFICATION

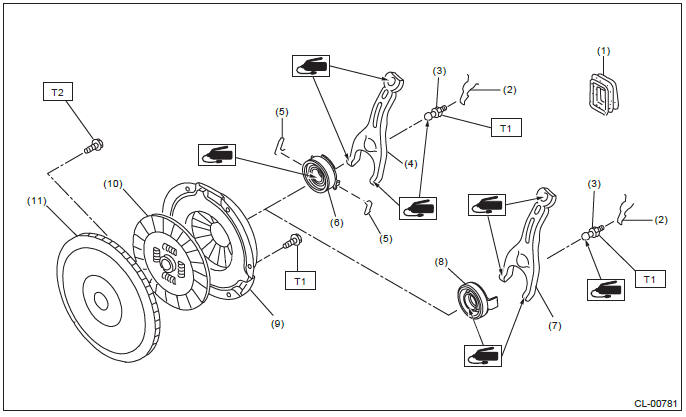

B: COMPONENT

1. CLUTCH ASSEMBLY

- Dust cover

- Lever spring

- Pivot

- Release lever (non-turbo model)

- Clip (non-turbo model)

- Release bearing (non-turbo model)

- Release lever (turbo model)

- Release bearing (turbo model)

- Clutch cover

- Clutch disc

- Flexible flywheel

Tightening torque: N*m (kgf-m, ft-lb)

T1: 16 (1.6, 11.8)

T2: 75 (7.6, 55.3)

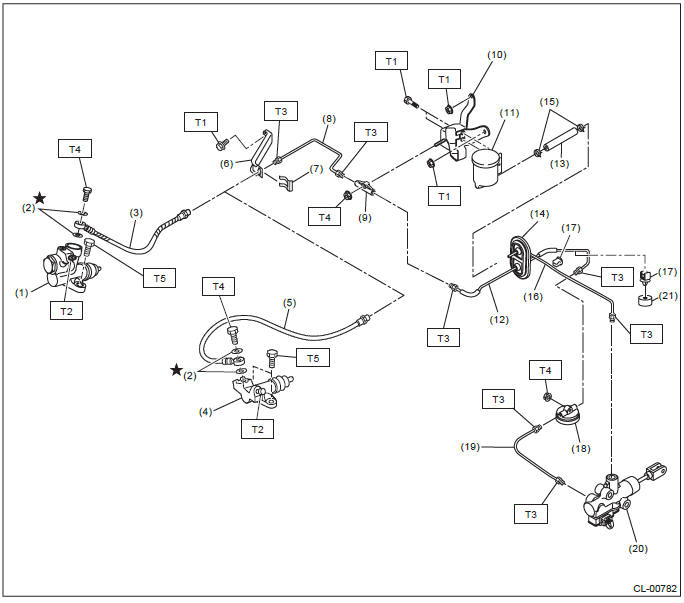

2. CLUTCH PIPE AND HOSE

- Operating cylinder (turbo model)

- Washer

- Clutch hose (turbo model)

- Operating cylinder (non-turbo model)

- Clutch hose (non-turbo model)

- Clutch hose bracket

- Clamp

- Clutch pipe

- Connector

- Reservoir tank bracket

- Reservoir tank

- Clutch pipe

- Reservoir tank hose

- Clutch pipe grommet

- Clamp

- Clutch pipe

- Clamp

- Clutch damper

- Clutch pipe

- Master cylinder ASSY

- Mass damper

Tightening torque: N*m (kgf-m, ft-lb)

T1: 7.5 (0.8, 5.5)

T2: 7.8 (0.8, 5.8)

T3: 15 (1.5, 11.1)

T4: 18 (1.8, 13.3)

T5: 37 (3.8, 27.3)

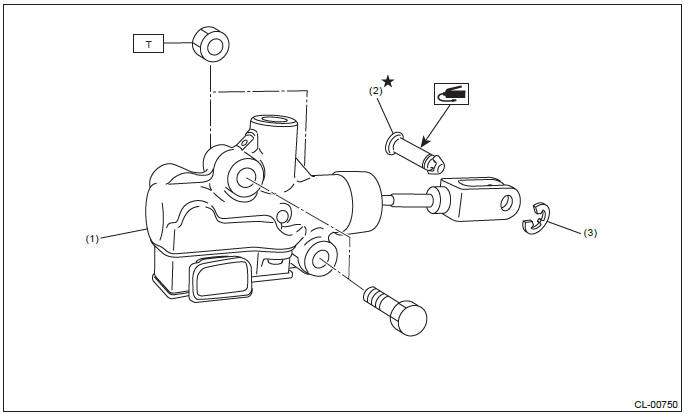

3. MASTER CYLINDER

- Master cylinder ASSY

- Clevis pin

- Clip

Tightening torque: N*m (kgf-m, ft-lb)

T: 18 (1.8, 13.3)

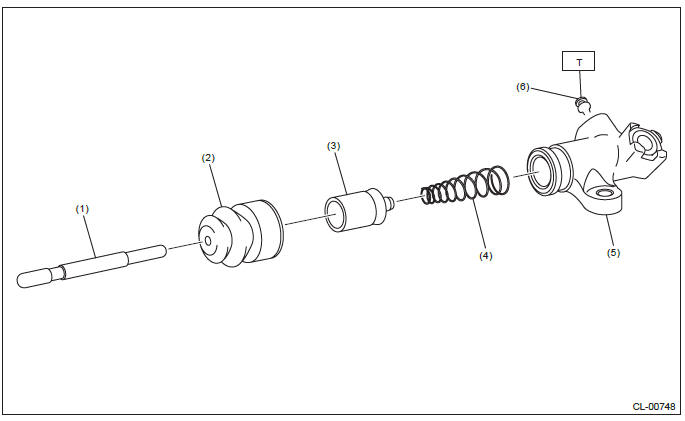

4. OPERATING CYLINDER

- Non-turbo model

- Push rod

- Boot

- Piston

- Piston spring

- Operating cylinder

- Breather screw

Tightening torque: N*m (kgf-m, ft-lb)

T: 7.8 (0.8, 5.8)

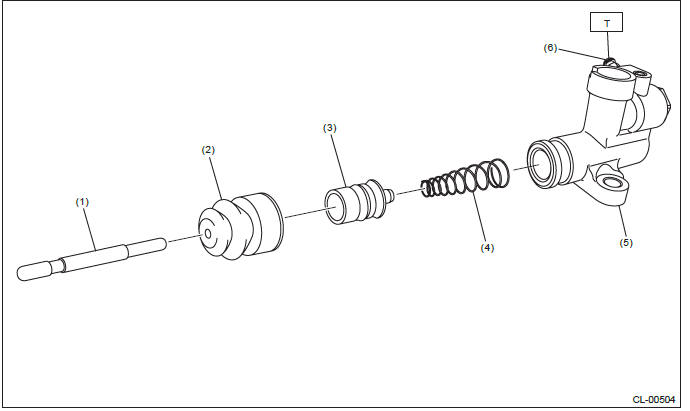

- Turbo model

- Push rod

- Boot

- Piston

- Piston spring

- Operating cylinder

- Breather screw

Tightening torque: N*m (kgf-m, ft-lb)

T: 7.8 (0.8, 5.8)

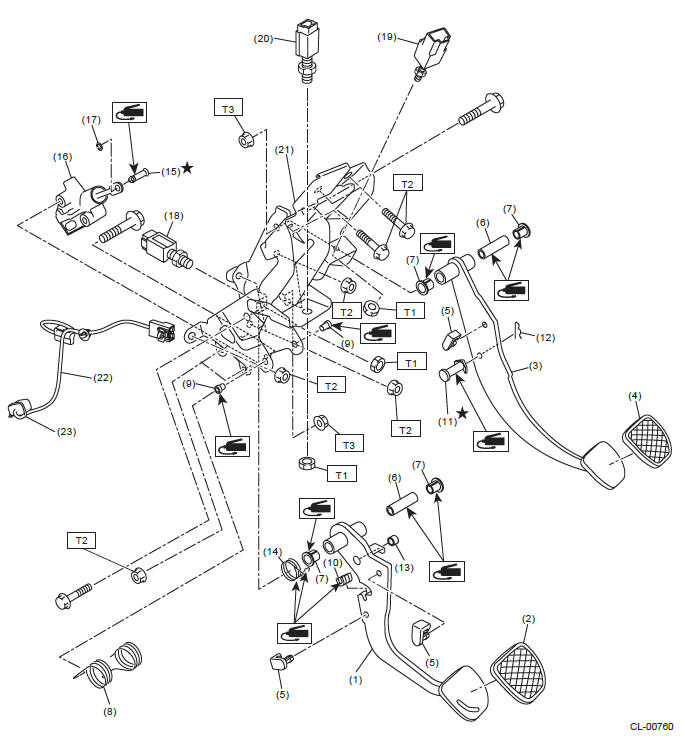

5. CLUTCH PEDAL ASSEMBLY

- Clutch pedal

- Clutch pedal pad

- Brake pedal

- Brake pedal pad

- Stopper

- Spacer

- Bushing

- Torsion spring

- Assist bushing

- Torsion spring bushing

- Clevis pin

- Snap pin

- Bushing A

- Assist spring (turbo model)

- Clevis pin

- Master cylinder ASSY

- Clip

- Clutch start switch

- Stop & brake switch

- Clutch switch

- Pedal bracket

- Sensor harness

- Band

Tightening torque: N*m (kgf-m, ft-lb)

T1: 8 (0.8, 5.9)

T2: 18 (1.8, 13.3)

T3: 30 (3.1, 22.1)

C: CAUTION

- Wear appropriate work clothing, including a cap, protective goggles and protective shoes when performing any work.

- Remove contamination including dirt and corrosion before removal, installation or disassembly.

- Keep the disassembled parts in order and protect them from dust and dirt.

- Before removal, installation or disassembly, be sure to clarify the failure. Avoid unnecessary removal, installation, disassembly and replacement.

- Vehicle components are extremely hot after driving. Be wary of receiving burns from heated parts.

- Use SUBARU genuine fluid, grease etc. or equivalent. Do not mix fluid, grease, etc. of different grades or manufacturers.

- Be sure to tighten fasteners including bolts and nuts to the specified torque.

- Place shop jacks or rigid racks at the specified points.

- Apply grease onto sliding or revolving surfaces before installation.

- Before installing O-rings or snap rings, apply sufficient amount of fluid to avoid damage and deformation.

- Before securing a part in a vise, place cushioning material such as wood blocks, aluminum plate or cloth between the part and the vise.

- Keep fluids away from the vehicle body. If any fluid contacts the vehicle body, immediately flush the area with water.

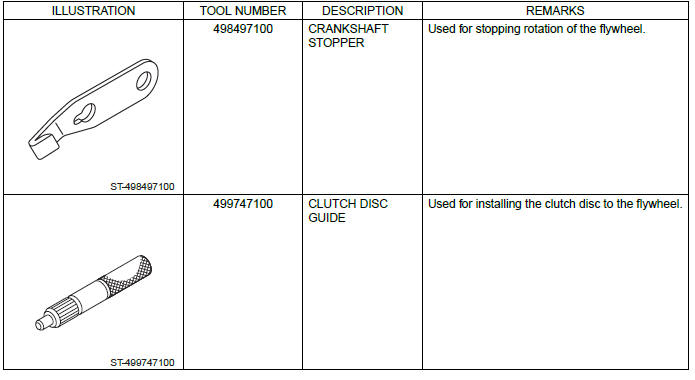

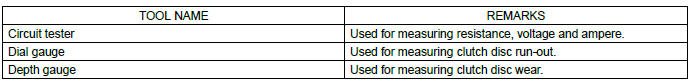

D: PREPARATION TOOL

1. SPECIAL TOOL

2. GENERAL TOOL

READ NEXT:

Clutch Disc and Cover

Clutch Disc and Cover

A: REMOVAL

1) Remove the transmission assembly from vehicle

body. <Ref. to 6MT-25, REMOVAL, Manual Transmission

Assembly.>

2) Attach the ST to the flywheel.

ST 499747100 CLUTCH DISC GUIDE

C

Flywheel

Flywheel

A: REMOVAL

1) Remove the transmission assembly. <Ref. to

6MT-25, REMOVAL, Manual Transmission Assembly.>

2) Remove the clutch cover and clutch disc. <Ref.

to CL-11, REMOVAL, Clutch Disc and

Operating Cylinder

Operating Cylinder

A: REMOVAL

NOTE:

The illustration below is suitable for every model.

Perform the same procedures for the other models.

1) Remove the collector cover. (turbo model)

2) Remove the air intake boot ass

SEE MORE:

Synthetic oil

Synthetic oil

You should use synthetic engine oil that meets the same requirements given for

conventional engine oil. When using synthetic oil, you must use oil of the same

classification, viscosity and grade shown in this Owner’s Manual. Refer to “Engine

oil” F12-4. Also, you must follow the oil and

Wiper operation when snowing

Wiper operation when snowing

Before driving in cold weather, make sure the wiper blades are not frozen to

the windshield or rear window.

If the wiper blades are frozen to the windshield or rear window, perform the

following procedure.

● To thaw the windshield wiper blades, use the defroster with the airflow selectio

© 2010-2025 Copyright www.suoutback.com