Subaru Outback (BR): General Description of Transmission Control Systems

Subaru Outback (BR) 2010-2015 Service Manual / Transmission / Control Systems / General Description of Transmission Control Systems

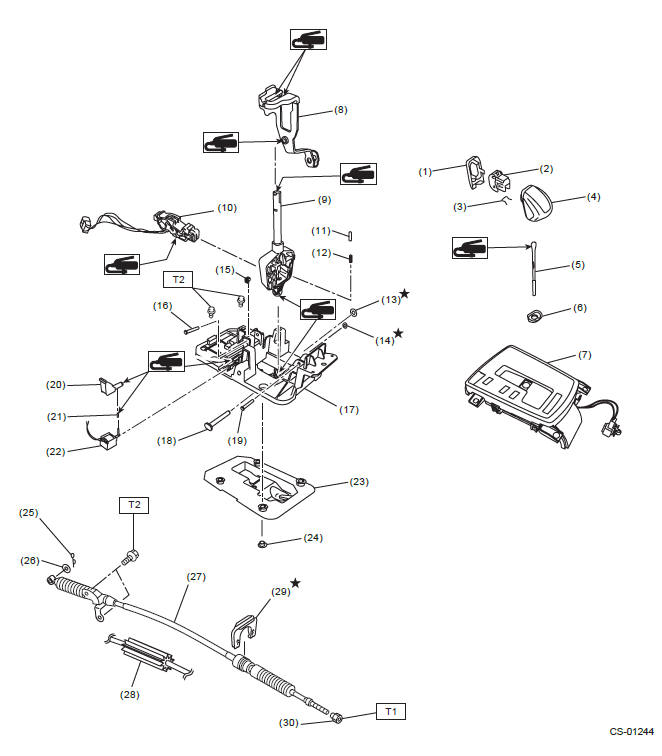

A: COMPONENT

1. AT SELECT LEVER

- Cover grip AT

- Button ASSY-AT

- Clamp grip pin

- Grip ASSY sub

- Rod COMPL

- Cover grip AT

- Indicator ASSY

- Arm ASSY

- Selector lever COMPL

- Plate guide

- Rod detent

- Detent spring

- Clamp push nut

- Clamp push nut

- Clamp pin

- Spacer pin guide

- Plate COMPL

- Shaft control

- Spacer pin guide

- Rod shift lock

- Cushion solenoid

- Solenoid unit

- Gasket

- Spacer plate

- Snap pin

- Washer

- Select cable (AT model)

- Select cable (CVT model)

- Clamp

- Nut

Tightening torque: N*m (kgf-m, ft-lb)

T1: 7.5 (0.8, 5.5)

T2: 18 (1.8, 13.3)

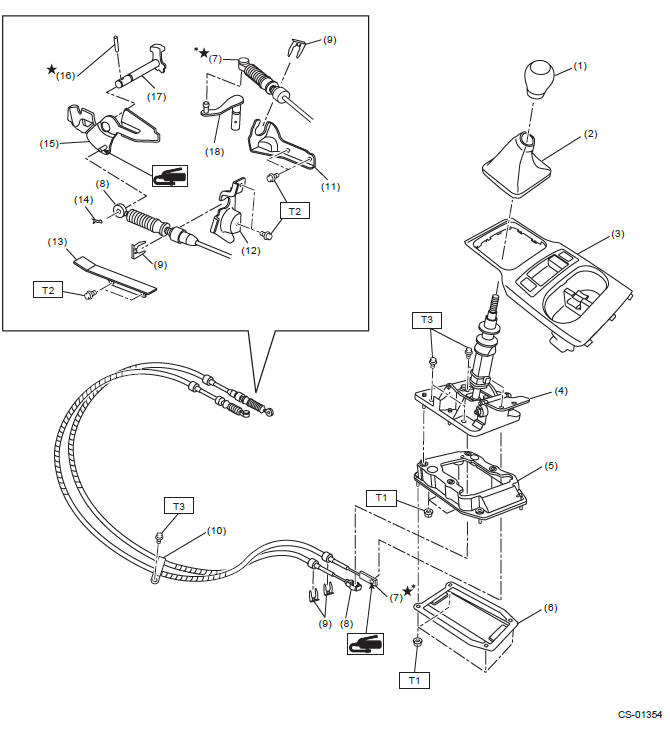

2. 6MT GEAR SHIFT LEVER

- Shift knob

- Shift boot

- Console front cover ASSY

- Gear shift lever ASSY

- Cover cable ASSY

- Plate cable ASSY

- MT gear select cable (identification tape color: green)

- MT gear shift cable (identification tape color: yellow)

- Clamp

- Clamp cable

- Select bracket

- Shift bracket

- Dust cover

- Snap pin

- Shift lever COMPL

- Spring pin

- Shifter arm No. 2

- Selector lever

Tightening torque: N*m (kgf-m, ft-lb)

T1: 7.5 (0.8, 5.5)

T2: 15 (1.5, 11.1)

T3: 18 (1.8, 13.3)

*: Always use new MT gear select cable if the cable is removed from select lever COMPL of transmission side.

B: CAUTION

- Wear appropriate work clothing, including a cap, protective goggles and protective shoes when performing any work.

- Remove contamination including dirt and corrosion before removal, installation or disassembly.

- Keep the disassembled parts in order and protect them from dust and dirt.

- Before removal, installation or disassembly, be sure to clarify the failure. Avoid unnecessary removal, installation, disassembly and replacement.

- Use SUBARU genuine fluid, grease or equivalent. Do not mix fluid and grease of different grades or manufacturers.

- Be sure to tighten fasteners including bolts and nuts to the specified torque.

- Place shop jacks or rigid racks at the specified points.

- Apply grease onto sliding or revolving surfaces before installation.

- Before installing the O-ring or snap ring, apply a sufficient amount of fluid to avoid damage and deformation.

- Before securing a part in a vise, place cushioning material such as wood blocks, aluminum plate or cloth between the part and the vise.

- Before disconnecting electrical connectors, be sure to disconnect the negative terminal from battery.

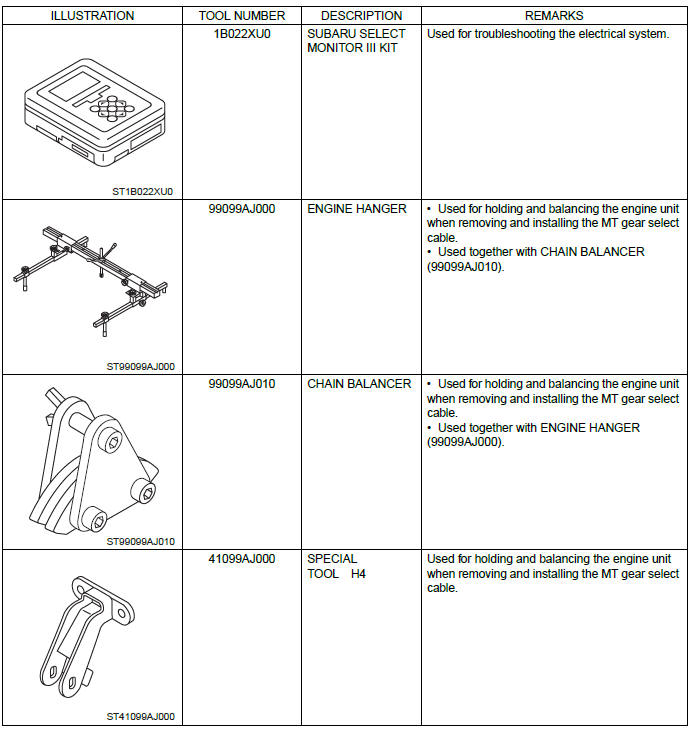

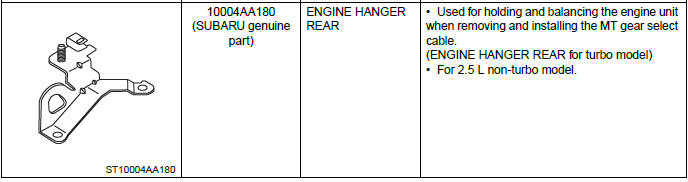

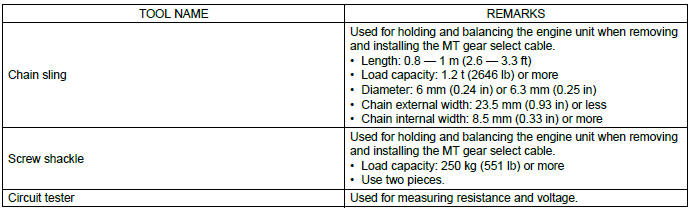

C: PREPARATION TOOL

1. SPECIAL TOOL

2. GENERAL TOOL

READ NEXT:

AT Shift Lock Control System

AT Shift Lock Control System

A: LOCATION

TCM ("P" range)

Body integrated unit

Stop light switch

Key cylinder (with built-in key

warning switch)

Solenoid unit

"P" range switch

Key lock solenoid

B: ELECTRICAL SPECIFICAT

Select Lever (removal, installation, disassembly, inspection)

Select Lever (removal, installation, disassembly, inspection)

A: REMOVAL

1) Shift the select lever to "N" range.

2) Disconnect the ground cable from battery.

3) Lift up the vehicle.

4) Remove the rear exhaust pipe.

2.5 L non-turbo model <

Select Cable

Select Cable

A: REMOVAL

1) Shift the select lever to "N" range.

2) Disconnect the ground cable from battery.

3) Lift up the vehicle.

4) Remove the front exhaust pipe and rear exhaust pipe.

2.5 L model

<Re

SEE MORE:

Electronic compass display

Electronic compass display

By briefly pressing the compass button, the compass display is toggled on or

off. When the compass display is on, an illuminated compass reading will appear

on the mirror.

Using the electronic compass properly, the following compass zone adjustment

and compass calibration will be necessary.

Child restraint systems

Child restraint systems

Infants and small children should always be placed in an infant or child restraint

system in the rear seat while riding in the vehicle.

You should use an infant or child restraint system that meets Federal Motor Vehicle

Safety Standards or Canada Motor Vehicle Safety Standards, is compatible

© 2010-2026 Copyright www.suoutback.com