Subaru Outback (BR): Oil Switching Solenoid Valve

A: REMOVAL

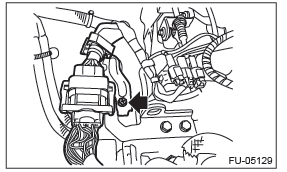

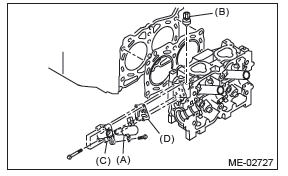

1. RH SIDE

1) Disconnect the ground cable from battery.

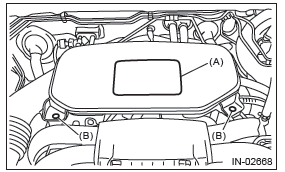

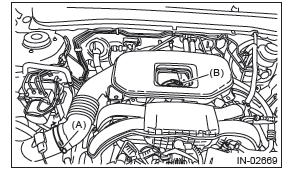

2) Remove the cover (A) and clip (B) from air intake boot assembly.

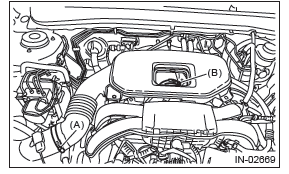

3) Loosen the clamp (A) which connects the air intake boot assembly and air cleaner case.

4) Loosen the clamp (B) which connects the air intake boot assembly and throttle body.

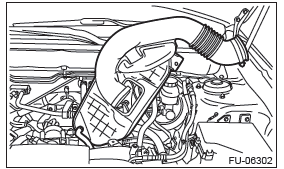

5) Remove the air intake boot from the throttle body, and move it to the left side wheel apron.

6) Remove the bolt, and disconnect the bulkhead harness connector from the engine harness connector and rear engine hanger.

7) Slide the engine harness connector in the direction of the arrow and remove it from the rear engine hanger.

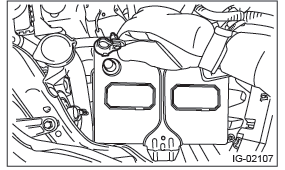

8) Disconnect the connector from the oil switching solenoid valve.

9) Remove the oil switching solenoid valve.

10) Remove the variable valve lift diagnosis oil pressure switch. <Ref. to FU(H4SO)-38, REMOVAL, Variable Valve Lift Diagnosis Oil Pressure Switch.>

11) Remove the oil temperature sensor. <Ref. to FU(H4SO)-40, REMOVAL, Oil Temperature Sensor.>

12) Remove the oil switching solenoid valve holder from the cylinder head.

- Oil switching solenoid valve

- Variable valve lift diagnosis oil pressure switch

- Oil temperature sensor

- Oil switching solenoid valve holder

- Gasket

- Washer

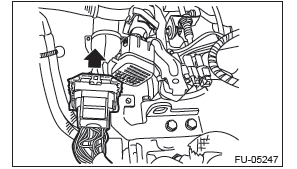

2. LH SIDE

1) Disconnect the ground cable from battery.

2) Remove the V-belts. <Ref. to ME(H4SO)-43, REMOVAL, V-belt.>

3) Remove the crank pulley. <Ref. to ME(H4SO)- 45, REMOVAL, Crank Pulley.>

4) Remove the timing belt cover. <Ref. to ME(H4SO)-47, REMOVAL, Timing Belt Cover.>

5) Remove the timing belt. <Ref. to ME(H4SO)-48, REMOVAL, Timing Belt.>

6) Remove the cam sprocket. <Ref. to ME(H4SO)- 53, REMOVAL, Cam Sprocket.>

7) Remove the timing belt cover No. 2 LH.

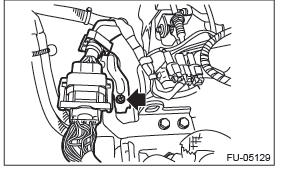

8) Disconnect the connector from the oil switching solenoid valve.

9) Remove the oil switching solenoid valve.

10) Remove the variable valve lift diagnosis oil pressure switch. <Ref. to FU(H4SO)-38, REMOVAL, Variable Valve Lift Diagnosis Oil Pressure Switch.>

11) Remove the oil switching solenoid valve holder from the cylinder head.

- Oil switching solenoid valve

- Variable valve lift diagnosis oil pressure switch

- Oil switching solenoid valve holder

- Gasket

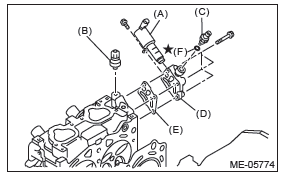

B: INSTALLATION

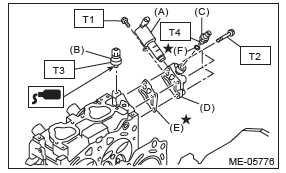

1. RH SIDE

Install in the reverse order of removal.

NOTE:

- Use a new gasket and washer.

- Apply liquid gasket to variable valve lift diagnosis oil pressure switch threads.

- Install the oil switching solenoid valve to the holder, then install it to the cylinder head.

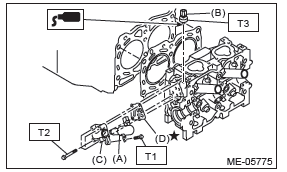

Tightening torque:

T1: 6.4 N*m (0.7 kgf-m, 4.7 ft-lb)

T2: 10 N*m (1.0 kgf-m, 7.4 ft-lb)

T3: 17 N*m (1.7 kgf-m, 12.5 ft-lb)

T4: 18 N*m (1.8 kgf-m, 13.3 ft-lb)

Liquid gasket:

THREE BOND 1324 (Part No. 004403042) or

equivalent

- Oil switching solenoid valve

- Variable valve lift diagnosis oil pressure switch

- Oil temperature sensor

- Oil switching solenoid valve holder

- Gasket

- Washer

Tightening torque: 6.4 N*m (0.7 kgf-m, 4.7 ft-lb)

NOTE: Align the clamp hole with the protrusion of the air intake boot assembly.

Tightening torque:

Clamp (A), (B)

3 N*m (0.3 kgf-m, 2.2 ft-lb)

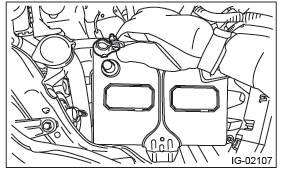

2. LH SIDE

Install in the reverse order of removal.

- NOTE:

- Use a new gasket.

- Apply liquid gasket to variable valve lift diagnosis oil pressure switch threads.

- Install the oil switching solenoid valve to the holder, then install it to the cylinder head.

Tightening torque:

T1: 6.4 N*m (0.7 kgf-m, 4.7 ft-lb)

T2: 10 N*m (1.0 kgf-m, 7.4 ft-lb)

T3: 17 N*m (1.7 kgf-m, 12.5 ft-lb)

Liquid gasket:

THREE BOND 1324 (Part No. 004403042) or

equivalent

- Oil switching solenoid valve

- Variable valve lift diagnosis oil pressure switch

- Oil switching solenoid valve holder

- Gasket

Intake and Exhaust Valve

A: SPECIFICATION

Refer to "Cylinder Head" for removal and installation procedures of the intake and exhaust valves.

<Ref. to ME(H4SO)-63, REMOVAL, Cylinder Head.> <Ref. to ME(H4SO)-63, INSTALLATION, Cylinder Head.>

Piston

A: SPECIFICATION

Refer to "Cylinder Block" for removal and installation procedures of pistons. <Ref. to ME(H4SO)-71, REMOVAL, Cylinder Block.> <Ref. to ME(H4SO)- 76, INSTALLATION, Cylinder Block.>

Connecting Rod

A: SPECIFICATION

Refer to "Cylinder Block" for removal and installation procedures of connecting rods. <Ref. to ME(H4SO)-71, REMOVAL, Cylinder Block.> <Ref. to ME(H4SO)-76, INSTALLATION, Cylinder Block.>

Crankshaft

A: SPECIFICATION

Refer to "Cylinder Block" for removal and installation procedures of the crankshaft. <Ref. to ME(H4SO)-71, REMOVAL, Cylinder Block.> <Ref. to ME(H4SO)-76, INSTALLATION, Cylinder Block.>

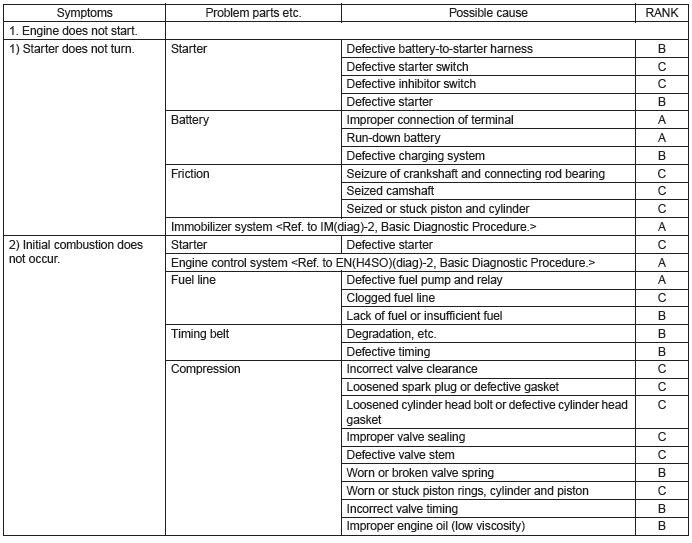

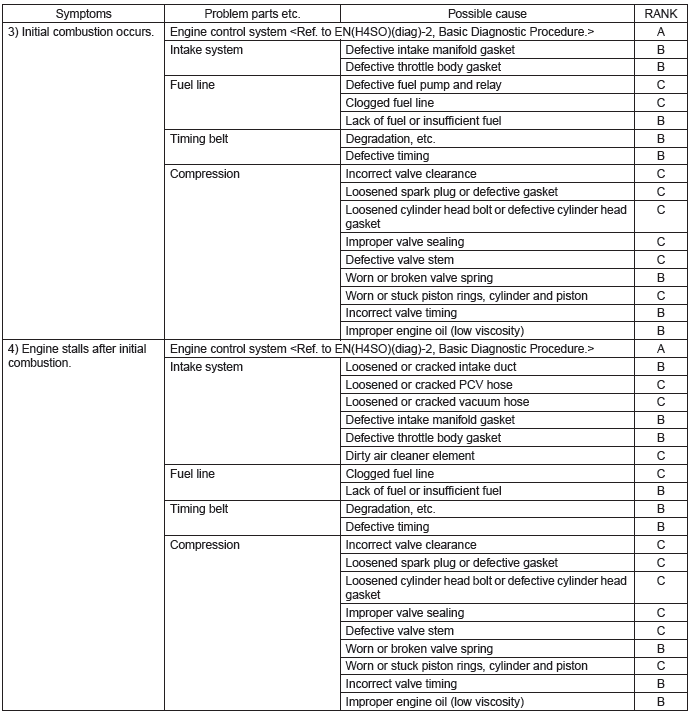

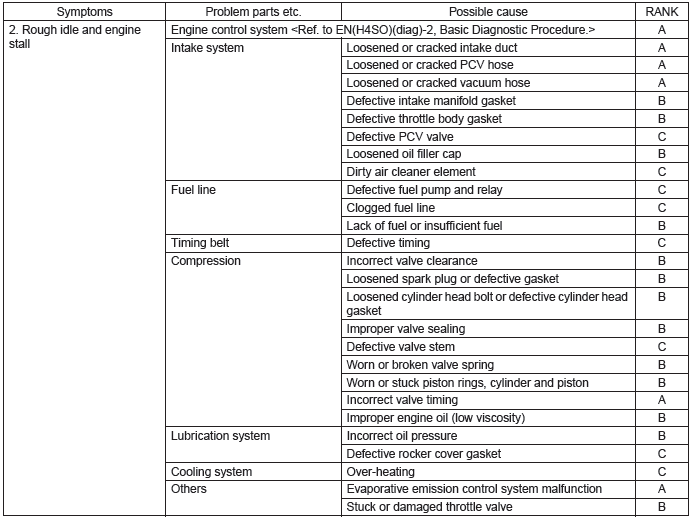

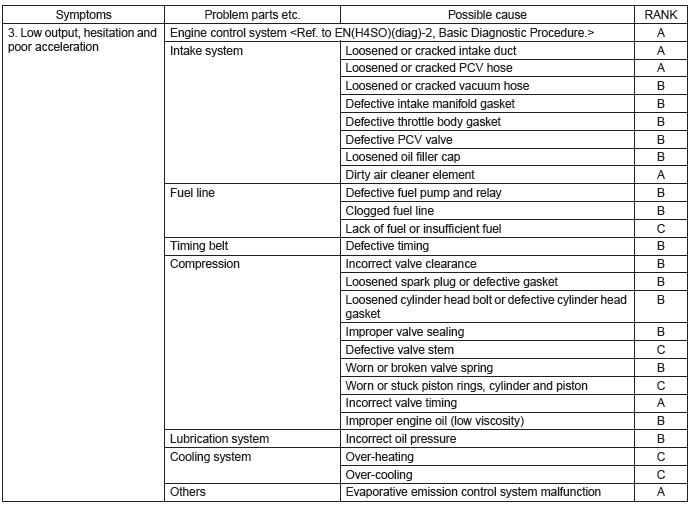

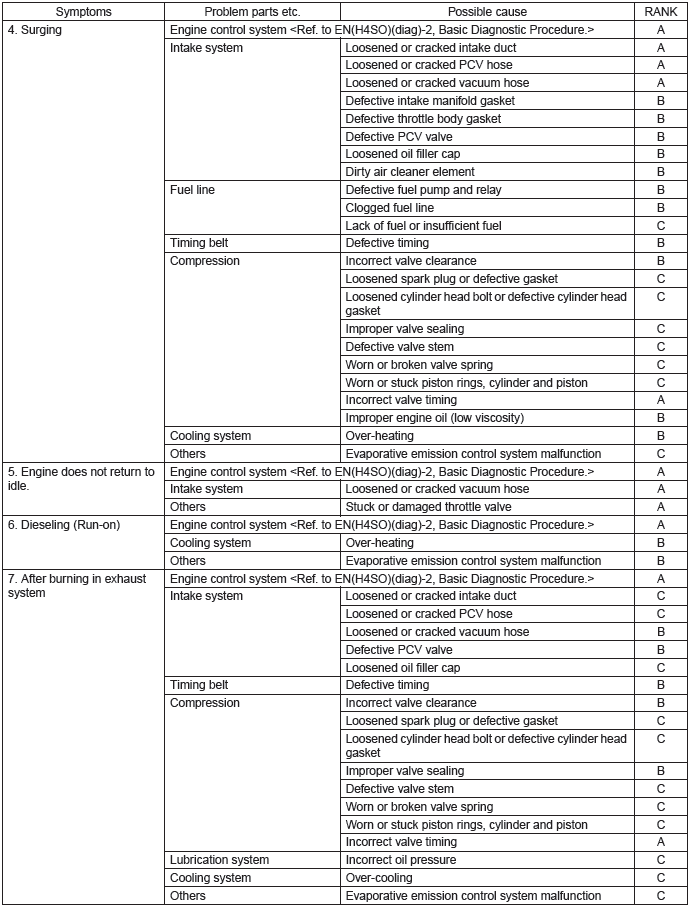

Engine Trouble in General

A: INSPECTION

NOTE: The "RANK" shown in the chart shows the possibilities of the cause of trouble in order from "Very often" to "Rarely".

A - Very often

B - Sometimes

C - Rarely

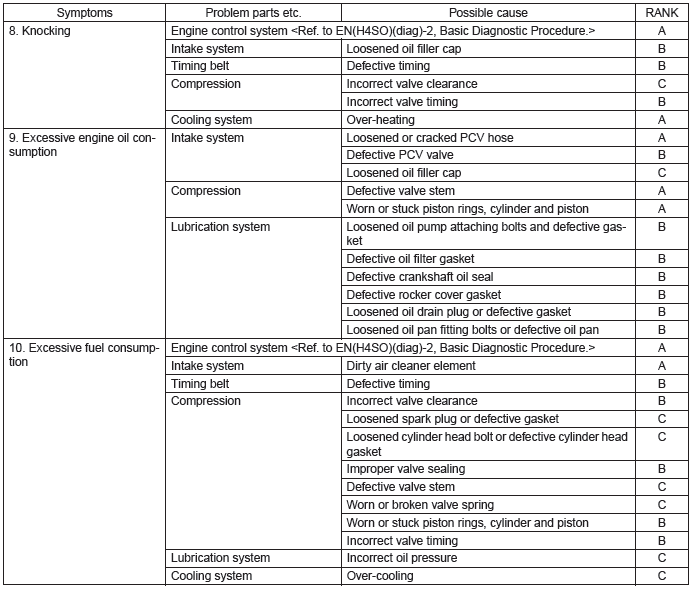

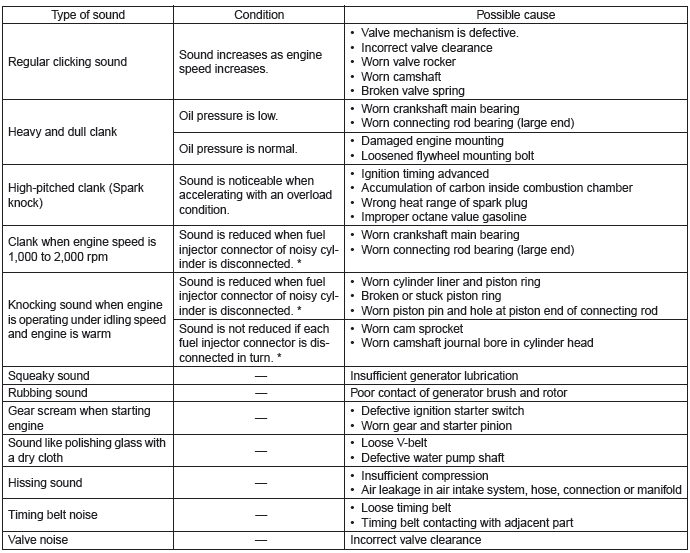

Engine Noise

A: INSPECTION

* When disconnecting the fuel injector connector, the malfunction indicator light illuminates and DTC is stored in ECM memory.

Therefore, perform the Clear Memory Mode <Ref. to EN(H4SO)(diag)-51, OPERATION, Clear Memory Mode.> and Inspection Mode <Ref. to EN(H4SO)(diag)-40, PROCEDURE, Inspection Mode.> after connecting the fuel injector connector.