Subaru Outback (BR): General Description of Vehicle Dynamics Control

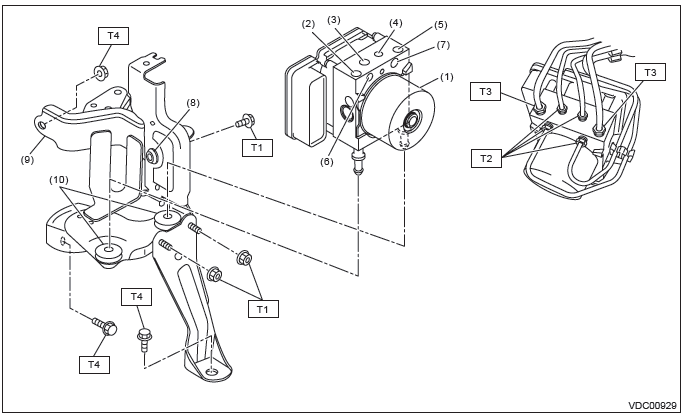

A: SPECIFICATION

B: COMPONENT

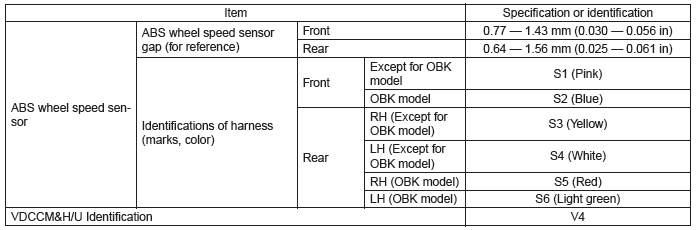

1. ABS WHEEL SPEED SENSOR

- Front ABS wheel speed sensor

- Front axle housing

- Rear ABS wheel speed sensor

- Rear axle housing

- Hub unit bearing

- Magnetic encoder

Tightening torque:N*m (kgf-m, ft-lb)

T: 7.5 (0.76, 5.5)

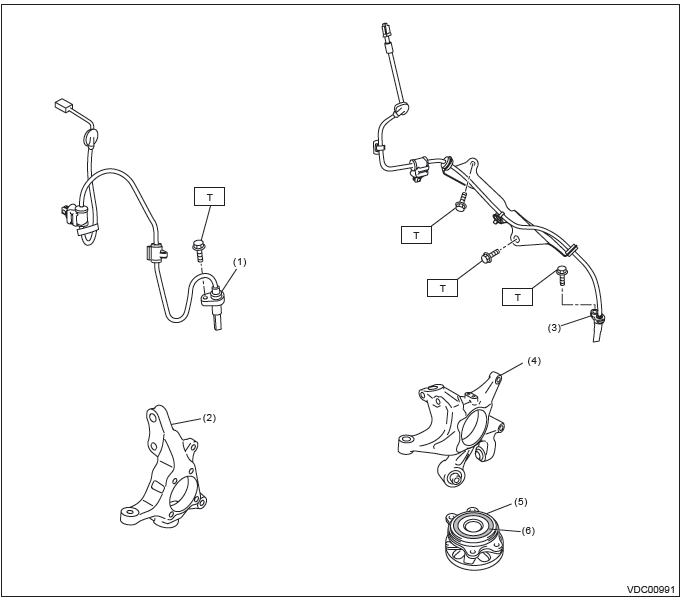

2. STEERING ANGLE SENSOR

- Steering roll connector

- Steering angle sensor

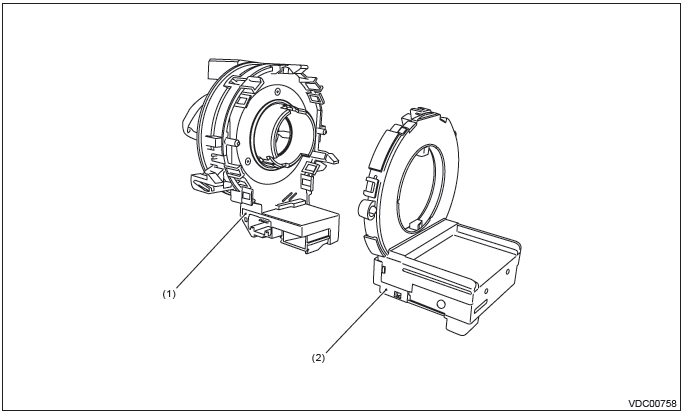

3. VDC CONTROL MODULE & HYDRAULIC CONTROL UNIT (VDCCM&H/U)

- VDC control module and hydraulic control unit (VDCCM&H/U)

- Secondary inlet

- Front LH outlet

- Front RH outlet

- Primary inlet

- Rear RH outlet

- Rear LH outlet

- Damper & spacer

- Bracket

- Damper

Tightening torque:N*m (kgf-m, ft-lb)

T1: 7.5 (0.76, 5.5)

T2: 15 (1.53, 11.1)

T3: 19 (1.94, 14.0)

T4: 33 (3.36, 24.3)

C: CAUTION

- Wear appropriate work clothing, including a helmet, protective goggles and protective shoes when performing any work.

- Remove contamination including dirt and corrosion before removal, installation or disassembly.

- Keep the disassembled parts in order and protect them from dust and dirt.

- Before disconnecting connectors of sensors or units, be sure to disconnect the ground cable from battery.

- Before removal, installation or disassembly, be sure to clarify the failure. Avoid unnecessary removal, installation, disassembly and replacement.

- Vehicle components are extremely hot after driving. Be wary of receiving burns from heated parts.

- Be sure to tighten fasteners including bolts and nuts to the specified torque.

- Place shop jacks or rigid racks at the specified points.

D: PREPARATION TOOL

1. SPECIAL TOOL

2. GENERAL TOOL

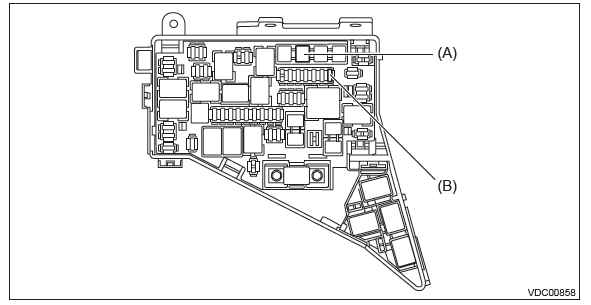

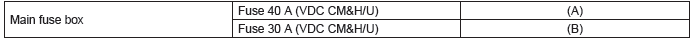

Relay and Fuse

A: LOCATION

NOTE: For other related fuses, refer to the wiring diagram. <Ref. to WI-15, Power Supply Circuit.>

B: INSPECTION

1. CHECK FUSE.

1) Remove the fuse and inspect visually.

2) If the fuse is blown out, replace the fuse.

Vehicle Dynamics Control System

A: WIRING DIAGRAM

Refer to "Vehicle Dynamics Control System" in the wiring diagram. <Ref. to WI-251, WIRING DIAGRAM, Vehicle Dynamics Control System.>

B: ELECTRICAL SPECIFICATION

Refer to the Control Module I/O Signal of the "Vehicle Dynamics Control System (VDC) (DIAGNOSTICS)".

<Ref. to VDC(diag)-12, ELECTRICAL SPECIFICATION, Control Module I/O Signal.>

C: INSPECTION

Refer to the "Vehicle Dynamics Control System (VDC) (DIAGNOSTICS)". <Ref. to VDC(diag)-90, INSPECTION, General Diagnostic Table.>

D: NOTE

For operation procedures of each component of the vehicle dynamics control system, refer to the respective section.

- VDC control module & hydraulic control unit (VDCCM&H/U): <Ref. to VDC-9, VDC Control Module and Hydraulic Control Unit (VDCCM&H/U).>

- Yaw rate & G sensor: <Ref. to VDC-23, Yaw Rate and G Sensor.>

- Steering angle sensor: <Ref. to VDC-24, Steering Angle Sensor.>

- Front ABS wheel speed sensor: <Ref. to VDC-29, Front ABS Wheel Speed Sensor.>

- Rear ABS wheel speed sensor: <Ref. to VDC-32, Rear ABS Wheel Speed Sensor.>

- Front magnetic encoder: <Ref. to VDC-34, Front Magnetic Encoder.>

- Rear magnetic encoder: <Ref. to VDC-35, Rear Magnetic Encoder.>

- VDC OFF switch: <Ref. to VDC-36, VDC OFF Switch.>