Subaru Outback (BR): General Description of Drive Shaft System

Subaru Outback (BR) 2010-2015 Service Manual / Chassis / Drive Shaft System / General Description of Drive Shaft System

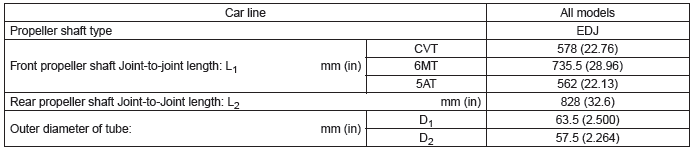

A: SPECIFICATION

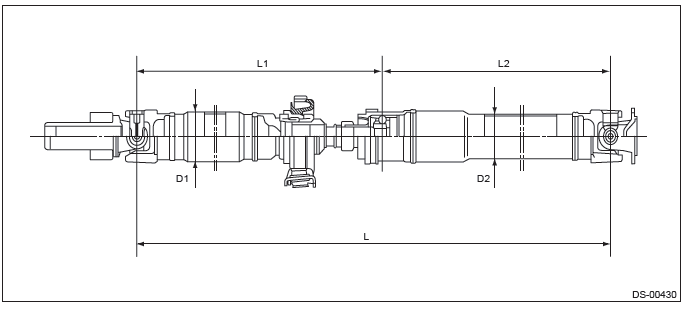

1. PROPELLER SHAFT

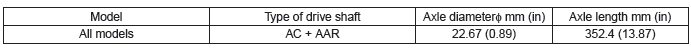

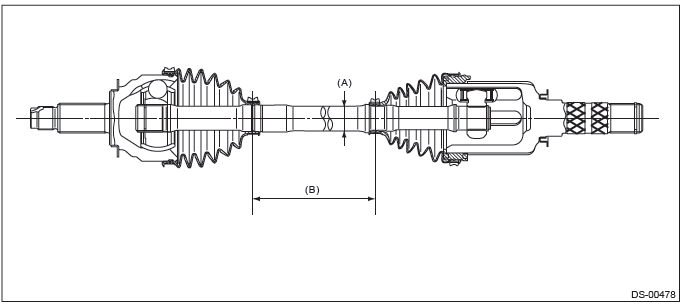

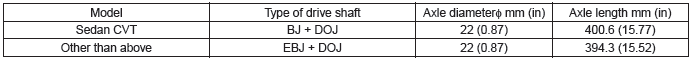

2. FRONT DRIVE SHAFT ASSEMBLY

- Axle diameter

- Axle length

3. REAR DRIVE SHAFT ASSEMBLY

- Axle diameter

- Axle length

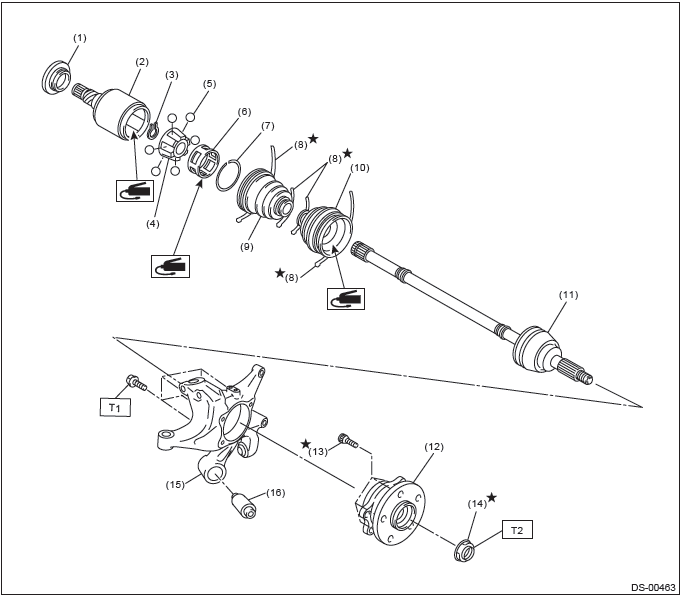

B: COMPONENT

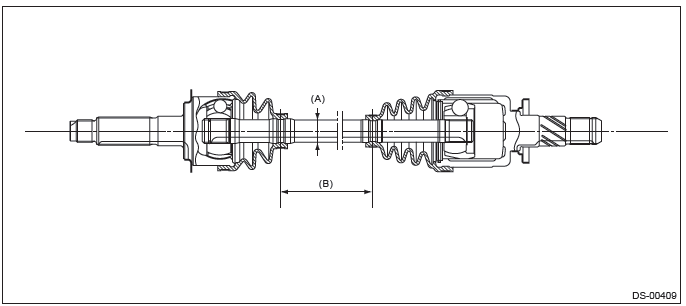

1. PROPELLER SHAFT

- Propeller shaft

- Rear differential (VA1-type)

- Rear differential (T-type)

- Rear differential (VA2-type)

Tightening torque: N*m (kgf-m, ft-lb)

T1: 31 (3.16, 22.9)

T2: 52 (5.3, 38.4)

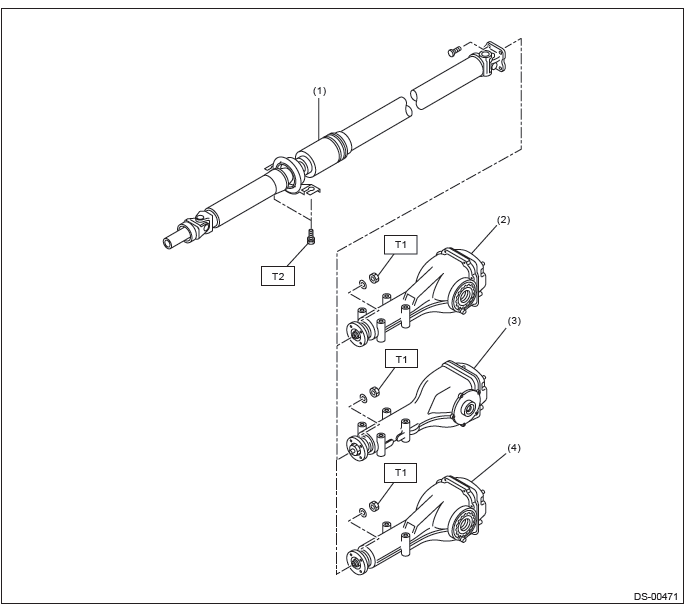

2. FRONT AXLE

- Circlip

- Baffle plate

- Outer race (AAR)

- Snap ring

- Trunnion

- Grommet

- Boot band

- Boot (AAR)

- AC shaft ASSY

- Boot (AC)

- Front axle housing

- Hub bolt

- Front hub unit bearing

- Axle nut

Tightening torque: N*m (kgf-m, ft-lb)

T1: 220 (22.43, 162.3)

T2: 65 (6.63, 47.9)

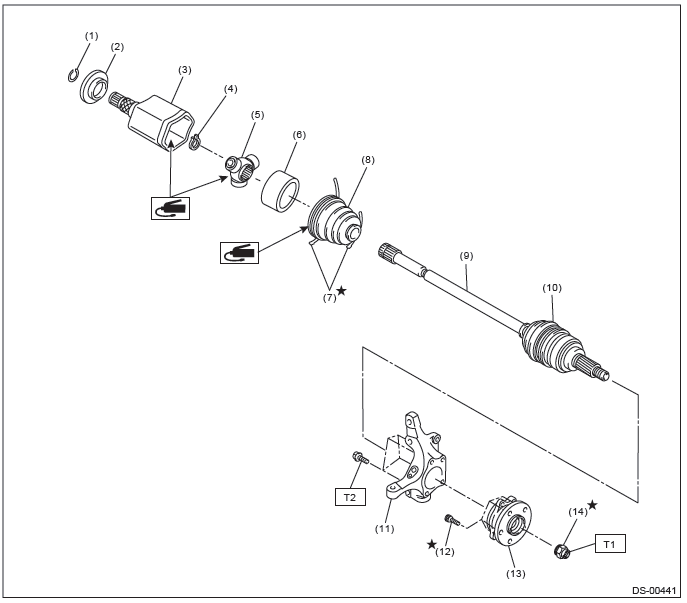

3. REAR AXLE

- Baffle plate

- Outer race (DOJ)

- Snap ring

- Inner race

- Ball

- Cage

- Snap ring

- Boot band

- Boot (DOJ)

- Boot (BJ)

- BJ shaft ASSY (sedan CVT model)

EBJ shaft ASSY (except for sedan CVT model) - Rear hub unit bearing

- Hub bolt

- Axle nut

- Rear axle housing

- Rear bushing

Tightening torque:N*m (kgf-m, ft-lb)

T1: 65 (6.63, 47.9)

T2: 240 (24.47, 177.0)

C: CAUTION

- Wear appropriate work clothing, including a helmet, protective goggles and protective shoes when performing any work.

- Remove contamination including dirt and corrosion before removal, installation or disassembly.

- Keep the disassembled parts in order and protect them from dust and dirt.

- Before removal, installation or disassembly, be sure to clarify the failure. Avoid unnecessary removal, installation, disassembly and replacement.

- Vehicle components are extremely hot after driving. Be wary of receiving burns from heated parts.

- Use SUBARU genuine grease etc. or equivalent. Do not mix grease etc. of different grades or manufacturers.

- Be sure to tighten fasteners including bolts and nuts to the specified torque.

- Place shop jacks or rigid racks at the specified points.

- Apply grease onto sliding or revolving surfaces before installation.

- Before installing snap rings, apply sufficient amount of grease to avoid damage and deformation.

- Before securing a part on a vise, place cushioning materials such as wood blocks, aluminum plates, or waste cloth between the part and the vise.

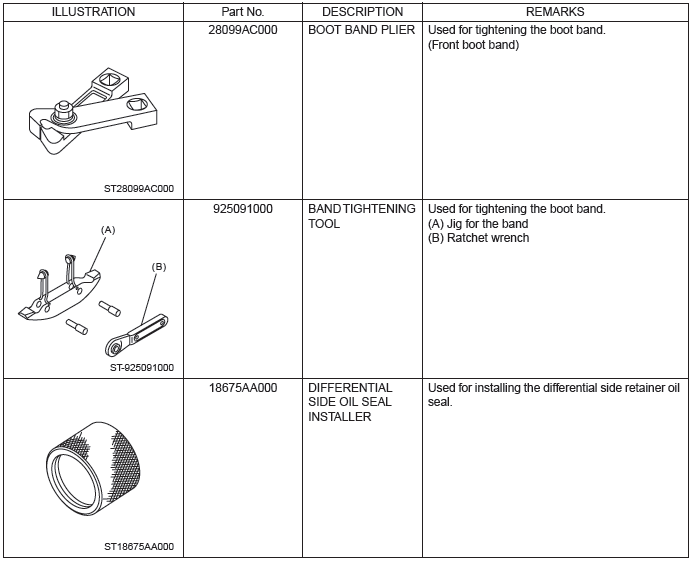

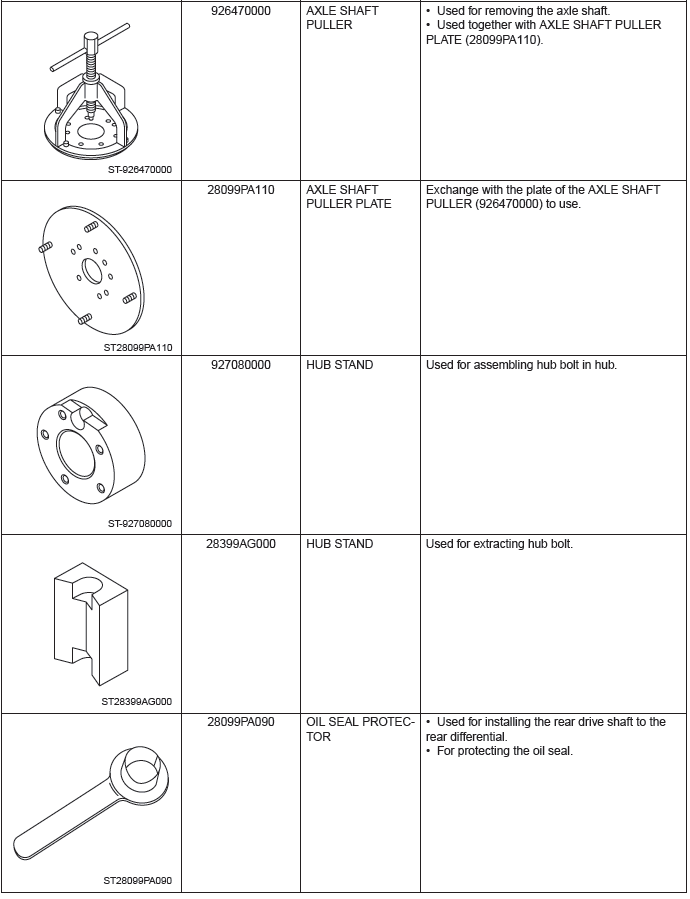

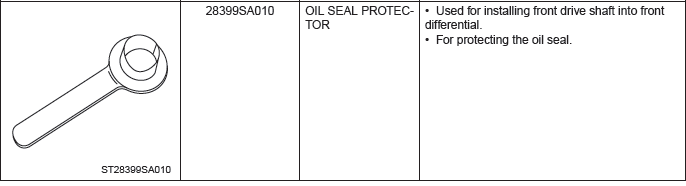

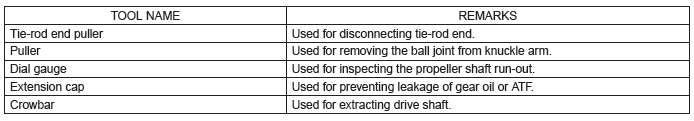

D: PREPARATION TOOL

1. SPECIAL TOOL

2. GENERAL TOOL

READ NEXT:

Propeller Shaft

Propeller Shaft

A: REMOVAL

CAUTION:

Do not disassemble the center EDJ of the propeller shaft.

Before removing propeller shaft, wrap the metal parts attached to the

rubber boot of center EDJ

with a cloth or rubb

Front Axle

Front Axle

A: REMOVAL

1) Lift up the vehicle, and then remove the front wheels.

2) Remove the axle nut.

CAUTION:

Do not loosen the axle nut while the front axle is loaded. Doing so may damage

the hub bearing.

Front Hub Unit Bearing

Front Hub Unit Bearing

A: REMOVAL

1) Lift up the vehicle, and then remove the front wheels.

2) Remove the axle nut.

CAUTION:

Do not loosen the axle nut while the front axle is loaded. Doing so may damage

the hub bearing.

SEE MORE:

Brake Booster

Brake Booster

A: REMOVAL

CAUTION:

Do not allow brake fluid to come in contact with the painted surface of the

vehicle body. If it does,

wash off with water and wipe away completely.

1) Disconnect the ground cable from battery.

2) Drain brake fluid from the reservoir tank completely.

3) Remove the master cylind

Crankshaft Position Sensor

Crankshaft Position Sensor

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the bolt which secures crankshaft position

sensor to oil pump.

3) Remove the crankshaft position sensor, and disconnect

the connector from the crankshaft position

sensor.

B: INSTALLATION

Install in the reverse order of removal.

Tig

© 2010-2025 Copyright www.suoutback.com