Subaru Outback (BR): General Description of Wiper and Washer Systems

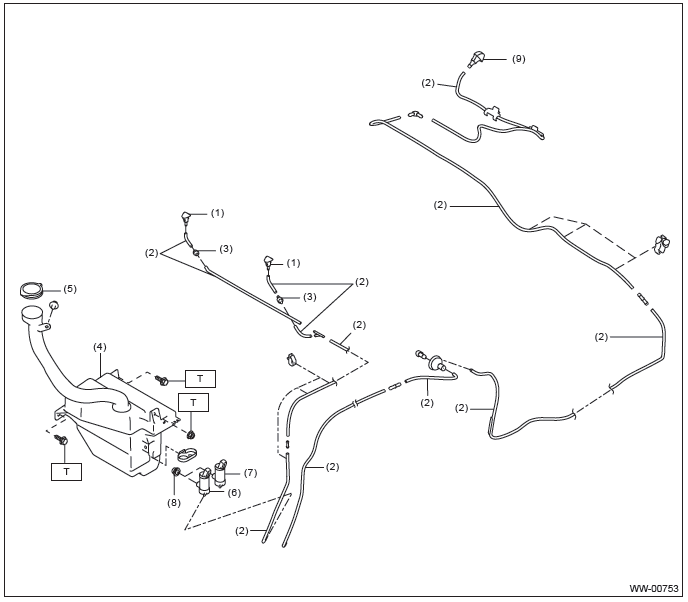

A: SPECIFICATION

B: COMPONENT

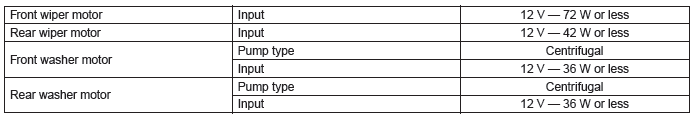

1. FRONT WIPER

- Wiper rubber

- Wiper blade ASSY

- Wiper arm ASSY

- Pivot cover B

- Wiper link ASSY

- Pivot cover C

- Wiper motor assembly

Tightening torque: N*m (kgf-m, ft-lb)

T1: 6 (0.61, 4.4)

T2: 7.5 (0.76, 5.5)

T3: 22 (2.24, 16.2)

T4: 32.1 (3.27, 23.7)

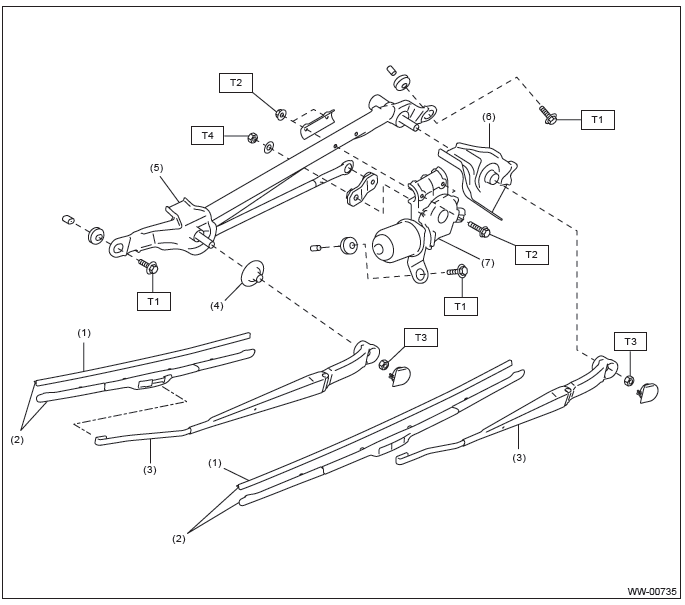

2. REAR WIPER

- Wiper rubber

- Wiper blade ASSY

- Wiper arm

- Wiper arm cover

- Pivot cap

- Wiper motor ASSY

Tightening torque: N*m (kgf-m, ft-lb)

T1: 7 (0.71, 5.2)

T2: 8 (0.82, 5.9)

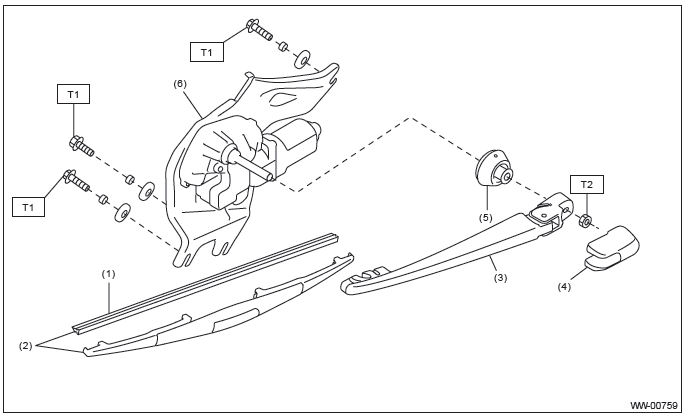

3. WASHER TANK

- Front washer nozzle

- Washer hose

- Check valve

- Washer tank

- Washer tank cap

- Front washer motor

- Rear washer motor (OUTBACK model only)

- Grommet

- Rear washer nozzle (OUTBACK model only)

Tightening torque: N*m (kgf-m, ft-lb)

T: 6 (0.61, 4.4)

C: CAUTION

- Connect the connectors and hoses securely during reassembly.

- After reassembly, make sure functional parts operates smoothly.

- Be careful with the airbag system wiring harness which passes near electrical parts and switches.

- Yellow connectors and harnesses with yellow tapes around them are the connectors and harnesses for the airbag system. Using a tester above such circuits may cause malfunction of airbag system. Follow the cautions for the airbag system in this case. <Ref. to AB-9, CAUTION, General Description.>

- When connecting the pipe hoses, be careful not to cause bend or blockage.

- If even a small amount of silicon oil or grease enters tank and washer fluid passages, an oil film will be formed on the glass and will cause the wiper to chatter and judder. Make sure that no oil comes into contact with the system.

D: PREPARATION TOOL

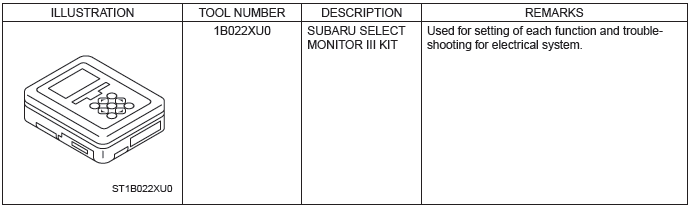

1. SPECIAL TOOL

2. GENERAL TOOL

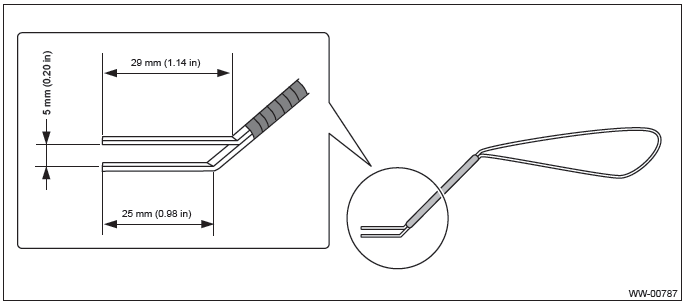

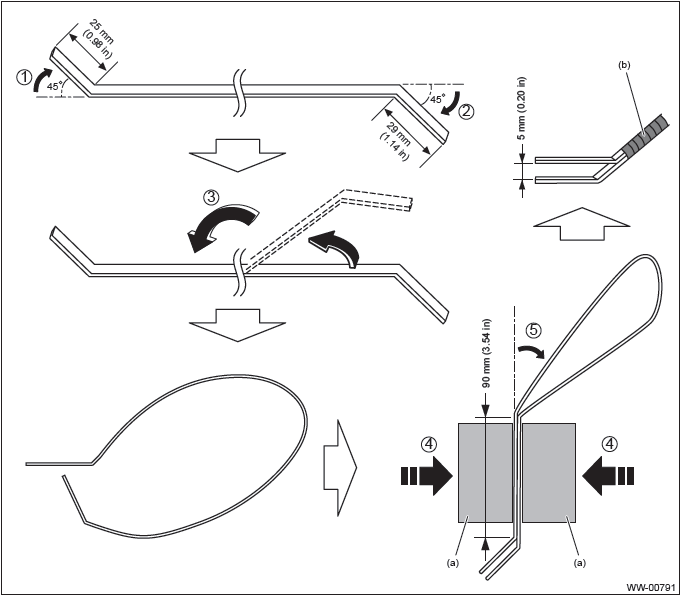

NOTE: Refer to the data described below, prepare the materials to make a front washer nozzle adjustment tool.

Materials

- Vertebra of wiper blade which is to be discarded

- Vinyl tape

Steps of making a front washer nozzle adjustment tool

1. Bend the vertebra at the position 25 mm (0.98 in) away from its end by 45º.

2. Bend the vertebra at the position 29 mm (1.14 in) away from the other end by 45º.

3. Double up the vertebra so that the longer end (29 mm (1.14 in) ) comes upward.

4. Secure the vertebra with a vise (a) so that the tip clearance becomes 5 mm (0.20 in).

5. Bend the vertebra at the position approximately 90 mm (3.54 in) away from the bending point for the longer end.

6. Check that the tip clearance is 5 mm (0.20 in), and secure the vertebra with vinyl tape (b).