Subaru Outback (BR): Rear Drive Shaft, General Diagnostic Table

A: REMOVAL

1) Lift up the vehicle, and then remove the rear wheels.

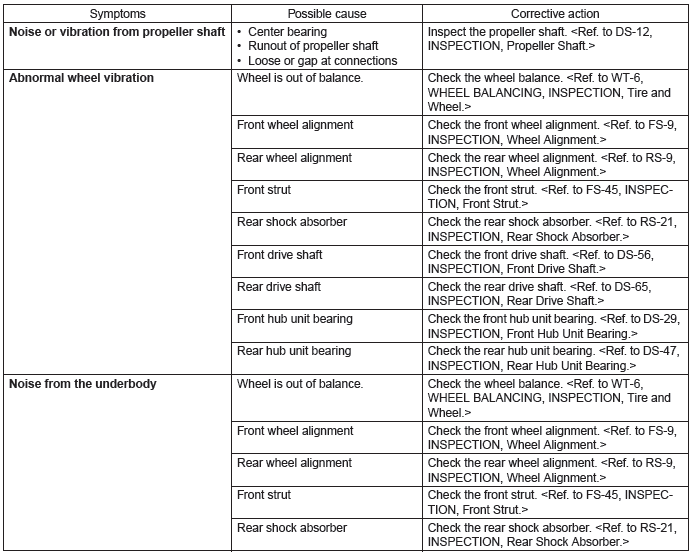

2) Remove the axle nut.

CAUTION: Do not loosen the axle nut while the rear axle is loaded. Doing so may damage the hub bearing.

- Lift the crimped section of axle nut.

- Remove the axle nut using a socket wrench while depressing the brake pedal.

3) Drain differential gear oil.

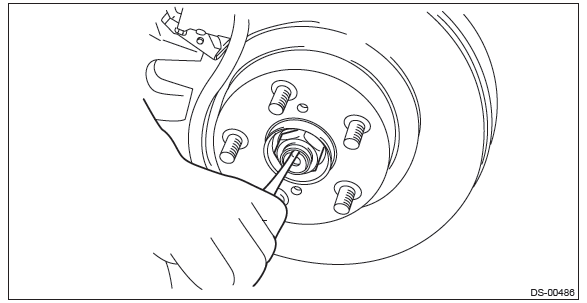

4) Remove the trailing link.

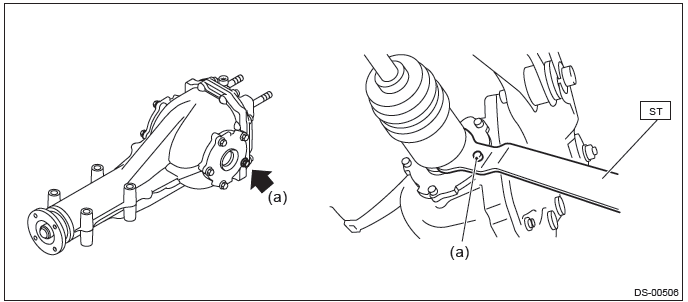

- Remove the bracket, and remove the parking brake cable from the guide (a).

- Remove the bolts and nuts, and then remove the trailing link.

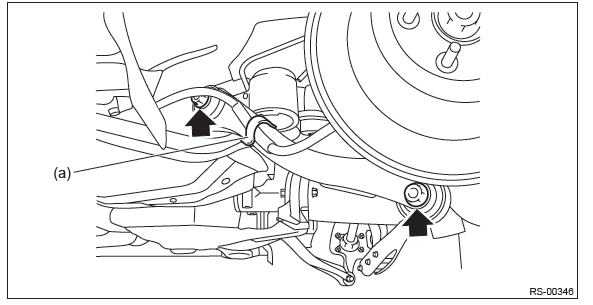

5) Remove the bolts and nuts and lower the rear lateral link.

- Remove the nut and disconnect the rear stabilizer link.

- Remove the shock absorber lower bolt.

- Disconnect the rear lateral link.

6) Remove the rear drive shaft from the rear differential.

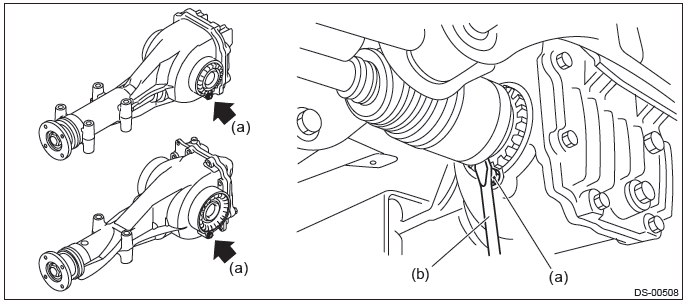

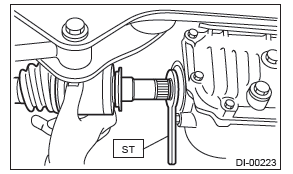

- T-type

1. Fit the ST to the bolt (a) as shown in the figure.

CAUTION: Fit the ST to the bolts as shown in the figure to prevent damage of the side bearing retainer.

PREPARATION TOOL: ST: DRIVE SHAFT REMOVER (28099PA100)

2. Extract the rear drive shaft from the rear differential.

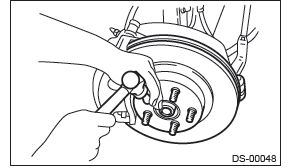

- VA-type

1. Fit the tire lever (b) to the bolt (a) as shown in the figure.

CAUTION: To prevent damage to the side bearing retainer, use by placing the tire lever against the bolt as shown in the figure.

Preparation tool: Tire lever

2. Extract the rear drive shaft from the rear differential.

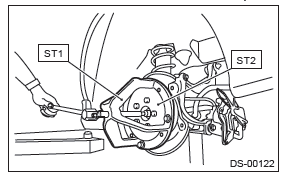

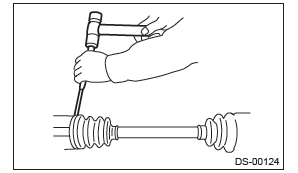

7) Remove the rear drive shaft from the rear axle.

NOTE: If it is hard to remove, use the ST.

PREPARATION TOOL:

ST1: AXLE SHAFT PULLER (926470000)

ST2: AXLE SHAFT PULLER PLATE (28099PA110)

B: INSTALLATION

1) Replace the rear differential side oil seal. <Ref. to DI-78, REPLACEMENT, Rear Differential Side Oil Seal.>

NOTE: After pulling out the drive shaft, be sure to replace with a new oil seal.

2) Insert the drive shaft into the rear hub spline, and pull the drive shaft into specified position.

CAUTION:

- Be careful not to damage the magnetic encoder.

- Do not get closer the tool which charged magnetism to magnetic encoder.

- Do not hammer drive shaft when installing it.

- Magnetic encoder

- Rear hub unit bearing

3) Tighten the axle nut temporarily.

4) Using the ST, install the rear drive shaft to the rear differential.

PREPARATION TOOL: ST: OIL SEAL PROTECTOR (28099PA090)

5) Attach the links to the rear housing and tighten them to the specified torque.

Tightening torque:

Stabilizer link: 33 N*m (3.4 kgf-m, 24.3 ft-lb)

Shock absorber: 120 N*m (12.2 kgf-m, 88.5 ft-lb)

Rear lateral link: 80 N*m (8.2 kgf-m, 59 ft-lb)

Trailing link - rear sub frame: 120 N*m (12.2 kgf-m, 88.5 ft-lb)

Trailing link - rear housing: 80 N*m (8.2 kgf-m, 59 ft-lb)

6) While pressing the brake pedal, tighten the new axle nuts to the specified torque.

CAUTION: Do not load the rear axle before tightening the axle nut. Doing so may damage the hub bearing.

Tightening torque: 240 N*m (24.47 kgf-m, 177 ft-lb)

7) Lock the axle nut securely.

8) Fill differential gear oil.

9) Install the rear wheels.

Tightening torque: 120 N*m (12.24 kgf-m, 88.5 ft-lb)

10) Inspect the wheel alignment and adjust if necessary.

- Inspection: <Ref. to FS-9, INSPECTION, Wheel Alignment.>

- Adjustment: <Ref. to FS-14, ADJUSTMENT, Wheel Alignment.>

C: DISASSEMBLY

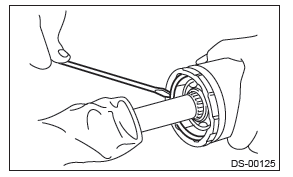

1) Take out the DOJ outer race from the shaft assembly.

CAUTION: Be careful not to damage the boot.

- Using a flat tip screwdriver or plier, loosen the boot band on the large end of DOJ boot.

CAUTION: Be careful not to damage the boot.

- Remove the boot band on the small end of DOJ boot in the same manner.

- Remove the large end of DOJ boot from DOJ outer race.

- Remove the round snap ring at the neck of DOJ outer race with a flat tip screwdriver.

- Take out the DOJ outer race from the shaft assembly.

- Wipe off the grease and take out the ball bearings.

CAUTION: The grease is a special grease (grease for constant velocity joints). Do not mix with other greases.

NOTE: Disassemble exercising care not to lose balls.

- Outer race

- Grease

2) Remove the cage from the inner race.

- Turn the cage by a half pitch to the track groove of inner race and shift the cage.

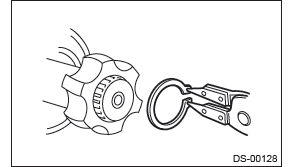

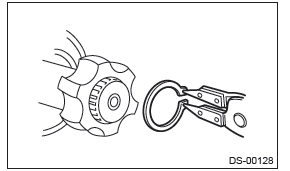

- Using pliers, remove the snap ring fixing the inner race to the shaft.

- Take out the DOJ inner race.

- Take off the DOJ cage from shaft and remove the DOJ boot.

CAUTION: Wrap shaft splines with vinyl tape to protect the boot from scratches.

3) Remove the BJ boot or EBJ boot in the same procedure as the DOJ boot.

NOTE: Further disassembly of the drive shaft is impossible because the BJ and EBJ cannot be disassembled.

D: ASSEMBLY

CAUTION: Wrap shaft splines with vinyl tape to protect the boot from scratches.

NOTE: Use specified grease.

BJ, EBJ side: NKG106

DOJ side: NKG205

1) Install the DOJ inner race to the shaft.

- Install the BJ or EBJ boot in specified position, and fill it with 50 to 60 g (1.76 to 2.12 oz.) of specified grease.

- Place the DOJ boot at the center of shaft.

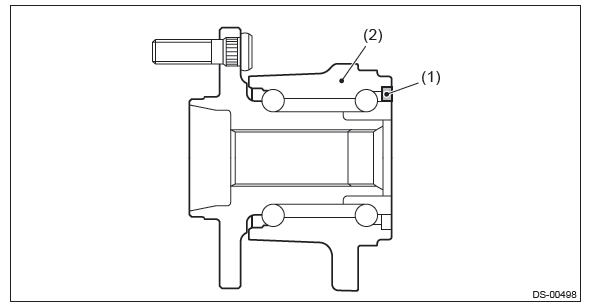

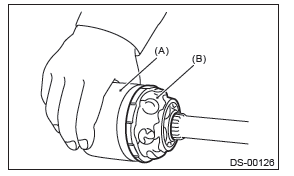

- Insert the DOJ cage onto shaft.

- Cage

- Cutout portion

NOTE: Insert the cage with the cutout portion facing the shaft end, since the cage has an orientation.

- Install the DOJ inner race on shaft and fix the snap ring in place with pliers.

NOTE: Confirm that the snap ring is completely fitted in the shaft groove.

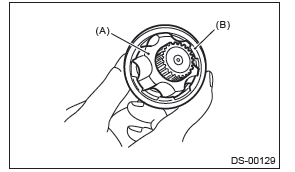

2) Install the cage to the inner race.

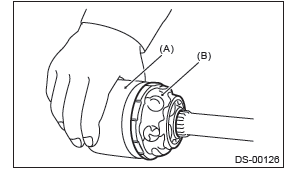

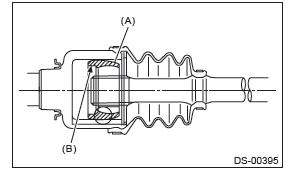

- Install the cage (B) with the protruding section aligned with the track on the inner race (A), and turn by a half pitch.

- Fill 80 to 90 g (2.82 to 3.17 oz) of specified grease into the inner side of the DOJ outer race.

- Apply a thin coat of specified grease to the cage pocket and ball.

- Insert the ball bearings into the cage pocket.

3) Connect the shaft assembly to the outer race.

- Align the outer race track and ball positions, and place the shaft, inner race, cage and ball bearings in the original positions, and then fix outer race in place.

- Outer race

- Grease

- Install the snap ring in the groove on the DOJ outer race.

CAUTION: Be careful of the following items during installation:

- Make sure that the balls, cage and inner race are completely fitted in the outer race of DOJ.

- Use care not to place the matched position of snap ring in the ball groove of outer race.

- Pull the shaft lightly and assure that the circlip is completely fitted in the groove.

- Apply an even coat of the specified grease [20 to 30 g (0.71 to 1.06 oz) ] to the entire inner surface of boot. Also apply grease to the shaft.

- Install the DOJ boot taking care not to twist it.

NOTE:

- The inside of the large end of DOJ boot and the boot groove shall be cleaned so as to be free from grease and other substances.

- When installing the DOJ boot, position the outer race of DOJ at center of the stroke.

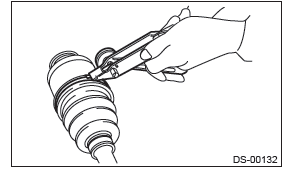

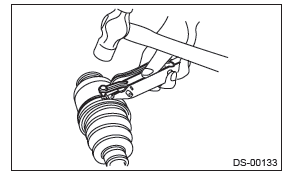

- Put a new band through the clip and wind twice in the band groove of the boot.

- Pinch the end of band with pliers. Hold the clip and tighten securely.

NOTE: When tightening boot, use care so that the air within the boot is appropriate.

- Tighten the band using the ST.

PREPARATION TOOL: ST: BAND TIGHTENING TOOL (925091000)

NOTE: Tighten the band until it cannot be moved by hand.

- Tap the clip with the punch provided at the end of the ST.

PREPARATION TOOL: ST: BAND TIGHTENING TOOL (925091000)

NOTE: Tap to an extent that the boot underneath is not damaged.

- Cut off the band with an allowance of about 10 mm (0.39 in) left from the clip and bend this allowance over the clip.

CAUTION: Make sure that the end of the band is in close contact with clip.

4) Install the BJ boot or EBJ boot in the same procedure as a DOJ boot.

5) Extend and retract the DOJ repeatedly to provide an equal coating of grease.

E: INSPECTION

Check the removed parts for damage, wear, corrosion etc. Repair or replace if defective.

- DOJ (Double Offset Joint): Check for seizure, corrosion, damage, wear and excessive play.

- EBJ (high-efficiency compact ball fixed joint): Check for seizure, corrosion, damage, wear and excessive play.

- Shaft: Check for excessive bending, twisting, damage and wear.

- BJ (Bell Joint): Check for seizure, corrosion, damage and excessive play.

- Boot: Check for wear, warping, breakage and scratches.

- Grease: Check for discoloration and fluidity.

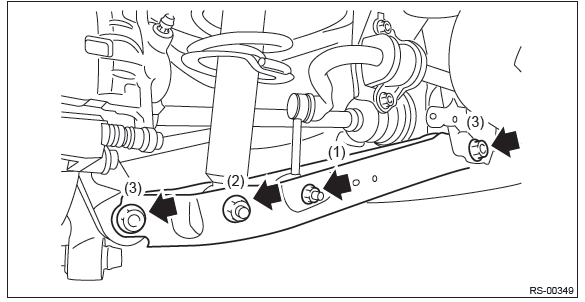

General Diagnostic Table

A: INSPECTION

NOTE: Vibration while cruising may be caused by an unbalanced tire, improper tire inflation pressure, improper wheel alignment, etc.